48

The easiest way to measure squish clearance is with 1mm to 1.5mm thick

flexible solder wire (available through most popular electronic stores). The

process is as follows:

Assemble the top end of the engine with either; 1) the crankcase stamp

recommended base gasket or, 2) if assembling with a new set of cases

assemble with a 0.4mm (0.015”) base gasket, and torque the head nuts to the

proper torque specifications leaving off the spark plug and ignition cover

(piston rings can be left off to ease of assembly).

Carefully insert the solder wire though the spark plug hole, into the cylinder

far enough such that the tip of the wire touches the left or right side cylinder

wall (not the front or back as the piston will rock more and give incorrect

measurement).

Hold the wire at this position and rotate the crankshaft, by the flywheel nut (or

kick lever) three revolutions to crush the solder wire.

CAUTION:

If you rotate the flywheel nut in a counterclockwise direction there is a risk of

loosening the nut.

Pull out the wire and measure the solder thickness at the thinnest location

near its tip accurately with the thin tips of calipers.

Adjust base gasket thickness as necessary to get the desired value.

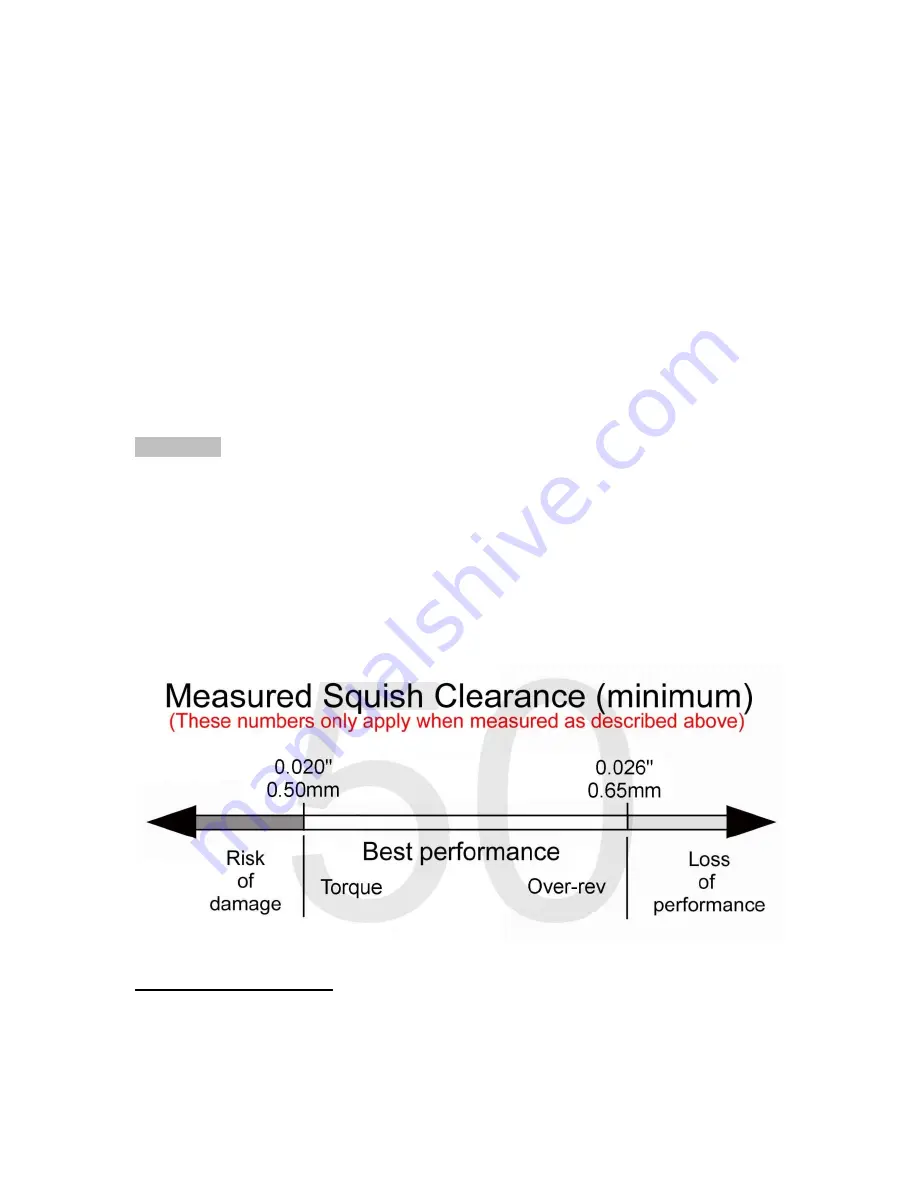

Upon completion, your final assembly squish clearance should agree with the

chart below:

CFD Adjustment

This section tells you what to do if you have tested and determined that the CFD

requires adjustment.

Summary of Contents for CX50P3

Page 23: ...23 This Page Intentionally Left Blank...

Page 24: ...24 Parts Engine Bottom End and Transmission...

Page 26: ...26 Parts Engine Clutch and Kick Lever...

Page 31: ...31 This page left intentionally blank...

Page 32: ...32 Parts Forks Triple Clamps...

Page 34: ...34 Parts Forks Leg Assembly...