15

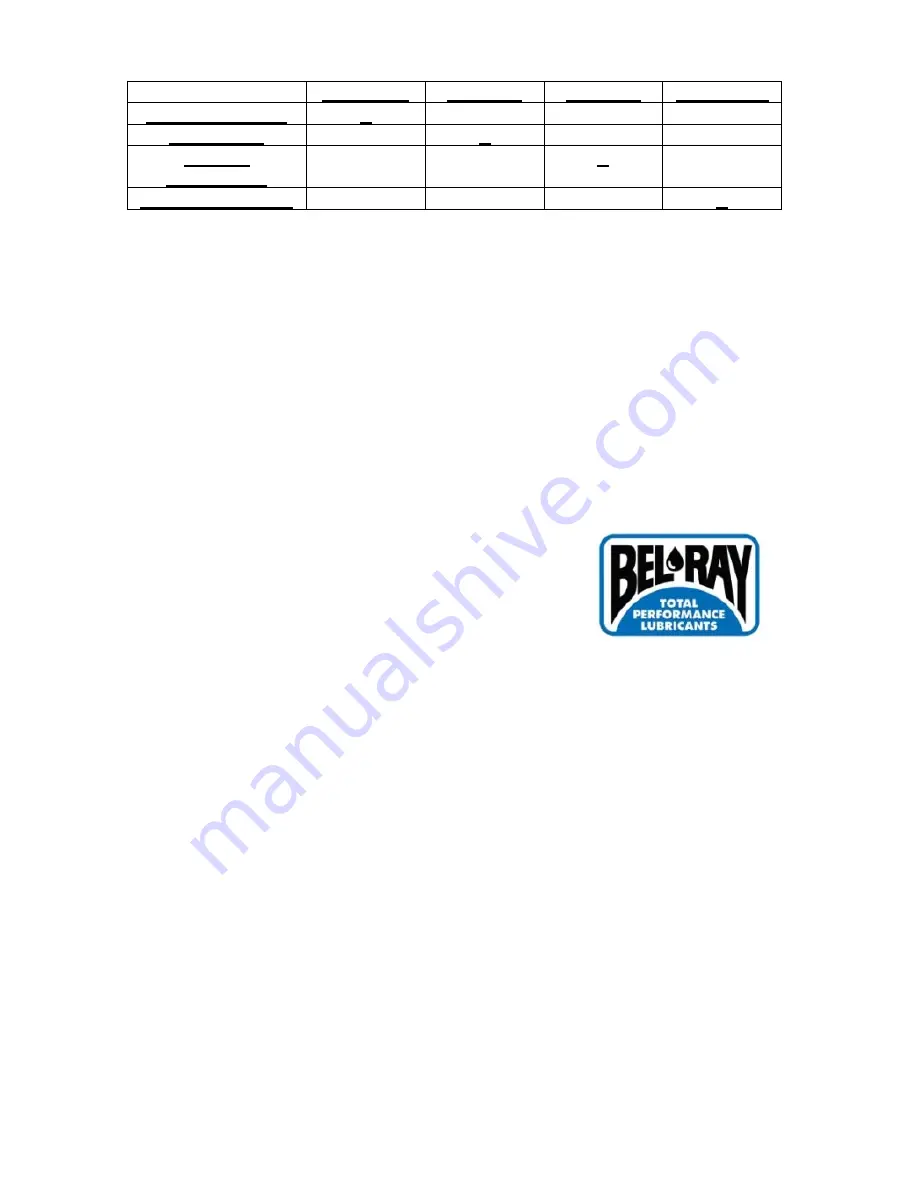

Each

Ride

10 hours

20 hours

As Needed

Bleed excess air

X

Change Oil

X

Change

Seal/Swiper

X

Change Bushings

X

Fork Air Bleeding

Tools required

3mm hex key (Allen wrench)

During normal operation, both fork legs will build up air pressure. This pressure

acts as an additional spring so it must be bled on a regular basis to maintain

consistent suspension operation. Before each ride, loosen the socket head cap

screw located at the front of each fork cap far enough so that any excess

pressure in the leg is relieved. After excess air is bled off, retighten the screw to 5

in-lb. Be careful not to lose or damage the sealing ring that is located under the

head of each bleed screw.

Fork Oil Replacement

Tools required

32mm Fork Cap Tool (MCMUTL32)

19mm wrench or socket

4 & 5 mm hex key (Allen wrench)

9/16

wrench

Mallet

2.5 wt. Bel-Ray fork oil

Disassembly procedure

1. Remove the front wheel (19 mm wrench).

2. Remove the brake caliper from the fork leg (4 mm hex key).

3. Loosen the fork caps (32mm fork cap tool).

4. Remove the fork legs from the triple clamps (5 mm hex key).

5. One leg at a time

a. Remove the fork cap from the fork tube.

b. Pull the fork spring down to gain access to the fork cap jam nut and

secure it with a 9/16 wrench.

c. Holding in one hand the 9/16 wrench use the fork cap wrench to

unscrew the fork cap from the damper rod.

d. Remove the fork spring pad, and fork spring.

e. Inside the damper rod, the rebound adjustment screw pin is resting

and will fall out of the damper rod when the fork is inverted. Try to

catch it before it falls into your oil bucket.

Summary of Contents for CX50P3

Page 23: ...23 This Page Intentionally Left Blank...

Page 24: ...24 Parts Engine Bottom End and Transmission...

Page 26: ...26 Parts Engine Clutch and Kick Lever...

Page 31: ...31 This page left intentionally blank...

Page 32: ...32 Parts Forks Triple Clamps...

Page 34: ...34 Parts Forks Leg Assembly...