T H E S M A R T S O L U T I O N F O R E N E R G Y E F F I C I E N C Y

13

c l i m a t e m a s t e r. c o m

Tr a n q u i l i t y 1 6 ( T C ) S e r i e s

R e v. : 2 5 J u l y, 2 0 1 7

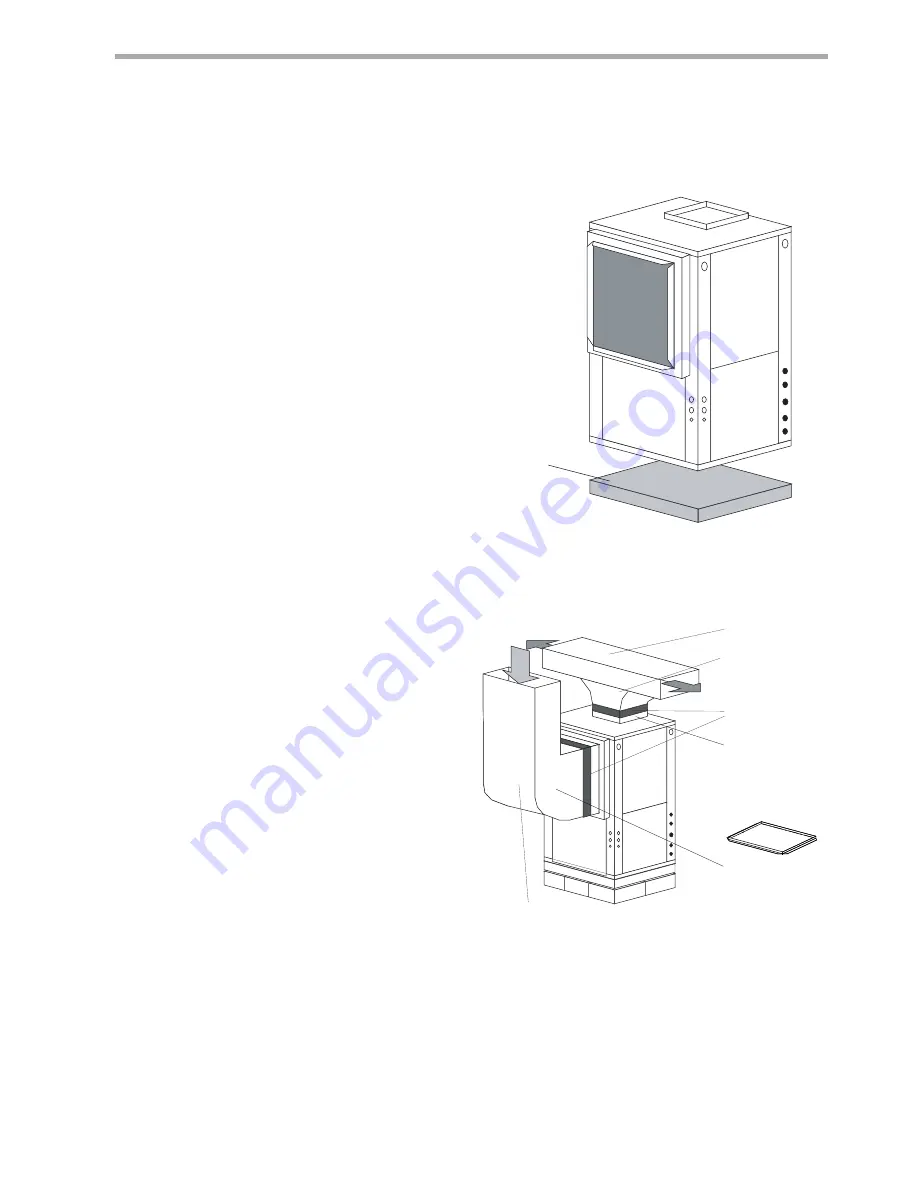

Vertical Installation

Vertical Unit Location

Units are not designed for outdoor installation. Locate

the unit in an INDOOR area that allows enough space

for service personnel to perform typical maintenance

or repairs without removing unit from the mechanical

room/closet. Vertical units are typically installed in a

mechanical room or closet. Never install units in areas

subject to freezing or where humidity levels could

cause cabinet condensation (such as unconditioned

spaces subject to 100% outside air). Consideration

should be given to access for easy removal of the fi lter

and access panels. Provide suffi cient room to make

water, electrical, and duct connection(s).

If the unit is located in a confi ned space, such as a

closet, provisions must be made for return air to freely

enter the space by means of a louvered door, etc. Any

access panel screws that would be diffi cult to remove

after the unit is installed should be removed prior to

setting the unit. Refer to Figures 7 and 8 for typical

installation illustrations. Refer to unit submittal data or

engineering design guide for dimensional data.

1. Install the unit on a piece of rubber, neoprene or

other mounting pad material for sound isolation.

The pad should be at least 10mm to 13mm in

thickness. Extend the pad beyond all four edges

of the unit.

2. Provide adequate clearance for fi lter replacement

and drain pan cleaning. Do not block fi lter access

with piping, conduit or other materials. Refer to

unit submittal data or engineering design guide

for dimensional data.

3. Provide access for fan and fan motor maintenance

and for servicing the compressor and coils without

removing the unit.

4. Provide an unobstructed path to the unit within

the closet or mechanical room. Space should be

suffi cient to allow removal of the unit, if necessary.

5. In limited side access installations, pre-removal of the

control box side mounting screws will allow control

box removal for future servicing (TC units only).

6. Provide access to water valves and fi ttings

and screwdriver access to the unit side panels,

discharge collar and all electrical connections.

Flexible canvas duct

connector to reduce

noise and vibration

Use turning vanes in

supply transition

Internally insulate supply

duct f

RUILUVWP

each way

to reduce noise

Internally insulate return

transition duct to reduce noise

Rounded return

transition

5HPRYHVXSSO\GXFW

IODQJHVIURPLQVLGHEORZHU

FRPSDUWPHQWDQGLQVWDOO

on supply air opening of

unit. Do not use a supply

DLUSOHQXPGXFWVPDOOHU

than the size of the supply

duct flanges.

Figure 8: Typical Vertical Unit Installation Using

Ducted Return Air

Air Pad or extruded

polystyrene insulation board

Figure 7: Typical Vertical Unit Mounting