20

Section 5

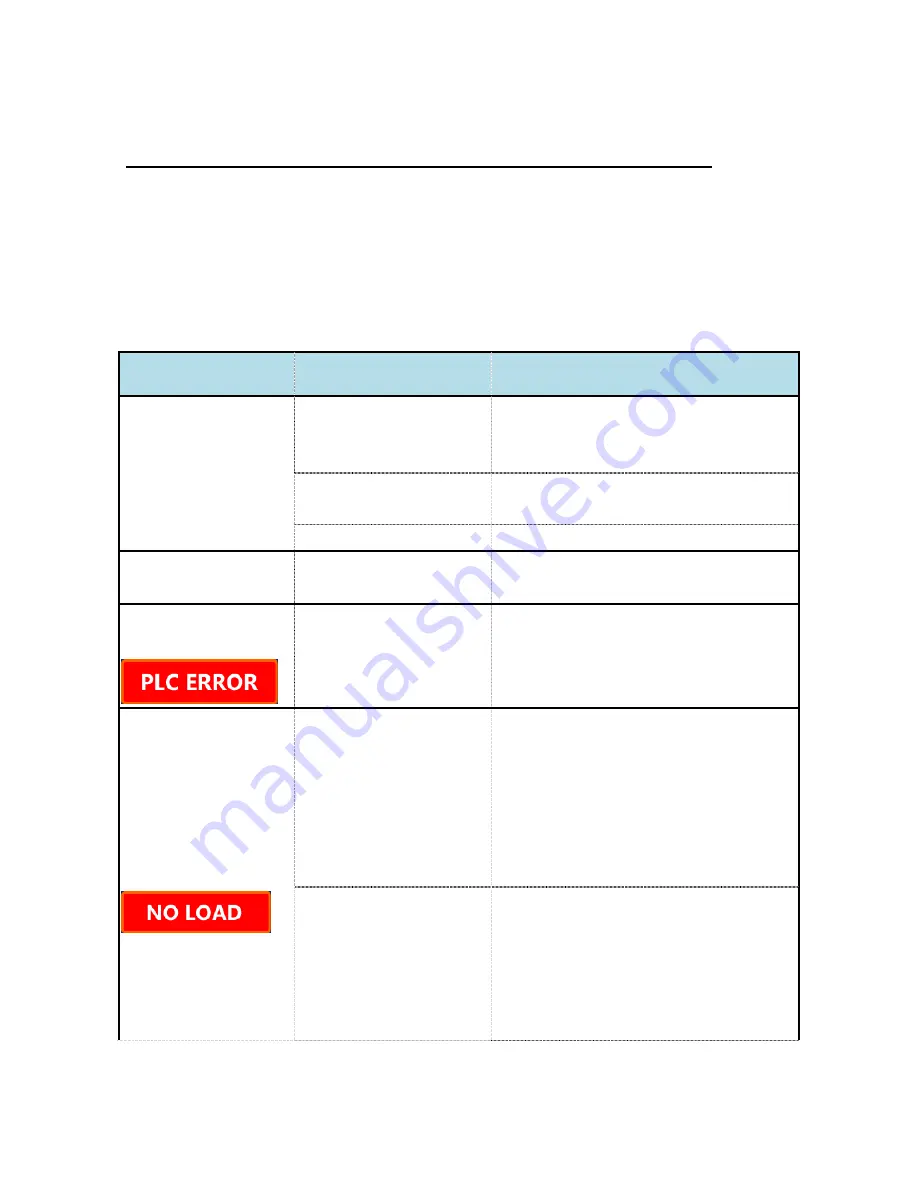

Trouble shooting and Maintenance

Many operating problems may be solved by carefully reading and following the

instructions in this manual accordingly. Some suggestions for troubleshooting are given

below. Should these suggestions not resolve the problem, contact our SERVICE

DEPARTMENT or a distributor in your region for assistance. If troubleshooting service is

required, please include a full description of the problem.

Problem

Possible Causes

Solution

No Display / lights

No AC power

Ø

Check if PowerPro power supply is

plugged, or AC power source has

problem.

AC power cord is not

connected

Ø

Check AC power cord connections at

both ends. Use the correct cords.

The fuse has blown

Ø

Replace the fuse.

Repeated fuse broken

Hardware failure

Ø

Contact Cleaver Scientific service

department

Operation stops and the

screen displays

Communication wires on

circuit board have loosen or

broken.

Ø

It is recommended to send the

machine back to local distributor or

our Service Department for

maintenance.

Operation stops with

alarm: The screen

displays

Electrophoresis leads are

not connected to the

power supply or to the

electrophoresis unit(s), or

there is a broken circuit in

the electrophoresis cell

Ø

Check the connections to the power

supply and on your electrophoresis cell

to make sure the connection is intact;

check condition of wires in

electrophoresis unit. Close the circuit

by reconnecting the cables. Press

START/STOP to restart the run.

High resistance due to tape

left on a pre-cast gel,

incorrect buffer

concentration, or incorrect

buffer volumes in the

electrophoresis cell

Ø

Make sure the tape is removed from

the pre-cast gel, buffers are prepared

correctly, and the recommended

volume of buffer is added to the

electrophoresis unit.