22

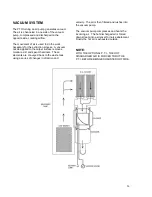

VACUUM PUMP DRIVE BELTS

To tighten the vacuum pump belts:

1.

Loosen the centre nut (left hand)that holds

the tensioner to the tensioner bracket.

2.

Using a tensioner wrench rotate the rear of

the tensioner to 75° for the Compact 45 or

47. For more information contact your local

authorized Cleanco service center.

3.

Roll the belts back onto the blower pulley.

The centre line on the inside of the tensioner

should be positioned between the second

and third line on the outside of the tensioner.

NOTE: When adjusting belt tension,

make certain that the PTO shaft and

vacuum pump shaft remain parallel,

and the belt tension is equal

throughout the belt width.

4.

After adjusting, check belt alignment with

straight-edge.

Make certain that when you re-torque these

screws, that you use a clockwise pattern and

continue until proper torque is achieved.

TORQUE VALUES

COMPONENT

INCH/LBS

FOOT/LBS

Rear PTO Hub

300

15

Vacuum Pump Hub

300

15

5.

Check for pulley groove wear, clean belts

and pulley grooves, check for worn belts, proper

belt tension, and pulley alignment after the

first

25 hours

and then again at

100 hours.

Check for belt ride in the groove.

PRESSURE REGULATOR

Lubricate the o-rings and bullet

every 50 hours.

Use o-ring lubricant or synthetic grease.

For the procedure, see the “General Service

Adjustments” section in this manual for details.

VACUUM HOSES

To assure maximum hose life, we recommend

that the hoses be washed out with clean water at

the end of each

working day.

HIGH PRESSURE HOSES

Inspect your high pressure hoses for wear after

the

first 100 hours

of use. Inspect

every 25

hours thereafter.

If hoses show any signs of

damage or impending rupture,

replace the

hose.

DO NOT attempt to repair high pressure

hoses! Repairing high pressure hoses

may result in severe burns and serious

injury!

All high pressure hoses must be rated for

3000 PSI at 250 deg F. Thermoplastic hoses

do not meet these specifications and should

not be used. Severe burns and injury may

result if the hoses do not meet these

requirements.

OPTIONAL WASTE PUMP-OUT

At the end of each work day

, make certain that

you remove any debris or sediment which may

be inside the waste pump by pumping fresh

water through the pump.

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...