8

DE-FLOODING OPERATIONS

De-flooding operations involve removal of water from

carpet and flooring. This differs from normal cleaning

operations in that no water or solution is required. A

Cleanco Auto Drain is recommended for all de-flooding

operations due to the large amount of water removal

often required.

1. Turn the MAIN POWER switch to the “CARPET

MODE”.

2. Leave pump switch “OFF” position.

FREEZE GUARD PROCEDURE

1.

Drain recovery and fresh water tanks.

2.

Remove chemical jug and store in a heated area.

3.

Remove hose from fresh water tank and insert into

a container of window washer antifreeze along with

the chemical feed hose.

4.

Turn chemical flow meter knob to the on position.

5.

Attach the fill (primer) hose to the front panel high

pressure quick connect and place other end into

an empty pail.

6.

Turn the unit switch and pump switch to the on

position.

7.

Open the ball valve on the fill (primer) hose.

8.

Chemical flow meter will begin to draw antifreeze

into the chemical injection system, continue until all

water is evacuated and antifreeze is present in the

flow being expelled into the pail.

9.

Close the fill (primer) hose ball valve for approx. 10

seconds. This allows antifreeze to circulate through

the bypass system. Then open the fill (primer)

hose ball valve and evacuate the remainder of the

water until antifreeze is present.

10. Turn off unit and pump switch.

11. Replace hose on fresh water tank and remove fill

(primer) hose.

12. The use of a 12 volt air compressor for connecting

to all cleaning tools and high pressure hoses to

evacuate water from lines and valves.

13. Remember to reclaim the antifreeze upon start up.

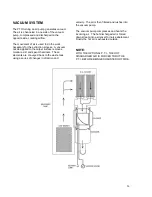

COMPACT WATER FLOW SYSTEM

The Compact water flow system has been design to be

simple and trouble free. The incoming water flows from

the fresh water tank through the incoming water filter,

then through the chemical injector. As the water passes

through the chemical injector, it automatically picks up

the predetermined quantity of cleaning solution.

The predetermined quantity of cleaning solution is

determined by the chemical flow meter located on the

front panel. With this advanced chemical injector, the

chemical flow is injected only when there is a demand

for water.

Once the water has been injected with the correct

amount of chemical it then passes through the high

pressure pump, where it is pressurized. The pressure is

then control by the BPR (Balanced Pressure Regulator),

which is fully adjustable from the front panel.

After the water flow exits the BPR (Balanced Pressure

Regulator), it then passes through the dual reverse flow

heat exchanger where the water is heated to the preset

temperature, which is determined by the adjustable

temperature control knob on the front panel.

The water then exits the heat exchangers and continues

through the plumbing system to the high pressure quick

connects located on the front panel.

NOTE:

The water flow plumbing system may need to be

flushed with vinegar periodically to prevent abnormal

chemical or hard water build-up. This can be done by

removing the clear hose from the chemical jug and

inserting it into a 1 liter (quart) container of vinegar. Then

open the chemical flow meter to the setting of 10. With

the unit running spray the wand until the 1 litre (quart) of

vinegar is empty. Then repeat the process with 1 litre

(quart) of water to flush the vinegar out of the lines.

If you are in an area with extreme hard water it is

suggested to use Coil Cleaner and flush entire water

system on a regular basis. For information on how to use

Coil Cleaner, contact your nearest Cleanco distributor.

HIGH PRESSURE PUMP

The Compact 45 & 47 are equipped with a state of the

art Cat plunger pump. Cat pumps are built to last, with

three ceramic plungers, stainless steel valves and oil-

cooled cam-shaft system.

With the Cat pump you have the ability of performing

carpet cleaning and power washing, with pressure

output ranging from 30 psi to 1200 psi. If 1200 psi is

exceeded this can cause damage to the packings and

retaining seals in the pump.

Your Cleanco Dis

tributor will preset your Compact unit’s

pump at a pressure rating between 300 psi and 500 psi

during installation. Cleanco has found this pressure

range to be the optimal setting for carpet cleaning. When

cleaning upholstery a simple adjustment of the BPR

(Balanced Pressure Regulator) on the front panel will

lower your pressure to 200 psi, which is recommended

for upholstery cleaning.

When power washing you must remember that your

Cleanco Compact is set up for carpet cleaning. Even

though your Triplex pump has maximum rating of 2500

psi, this pump is set up for carpet cleaning will give you

maximum 1200 psi for power washing. With 1200 psi

and the high heat from the Cleanco heat exchangers it

makes power washing simple.

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...