6

GENERAL INFORMATION

The Cleanco Compact Truckmount has been designed

for the professional cleaner who demands a high

performance cleaning unit. Dependable performance is

the guiding principal in the design and construction of

the Cleanco Compact. Although the Cleanco Compacts

are designed with simplicity in mind, this truckmounted

carpet cleaning plant has many functions that perform

simultaneously.

Engine has to run at a continuous RPM. (Van

Engine 1450 RPM)

High Pressure water pump provides steady pressure

at the proper flow for cleaning.

Vacuum Blower has to pull air and soiled water back

from the site.

Cleaning solution has to be injected into the water

flow at the right concentration.

Heating system must deliver and maintain proper

heat.

The vacuum recovery tank stores soiled water for

proper disposal.

This manual contains operation instructions as well as

information required for proper maintenance,

adjustments, and repair of this unit. To assist with proper

diagnosis of a problem, a general troubleshooting has

been included for your convenience.

LOCAL WATER CONDITIONS

The quality of water varies greatly throughout North

America. This can

influence the reliability and efficiency

of your equipment. Many areas have an excess of

minerals in the water, which results in what is known as

hard water. These minerals tend to adhere to the inside

of heat exchangers and other parts of the machines

causing damage and loss of cleaning effectiveness.

Cleaning effectiveness and equipment life is increased

when water softeners are used in hard water areas. The

low cost of water softeners is more than made up for by

the increased life of machine parts and cleaning

efficiency.

WASTE WATER DISPOSAL

There are laws throughout North America that prohibit

the dumping of soiled water from carpet cleaning

equipment in any place but a sanitary treatment system.

The water recovered into your unit’s recovery tank

contains materials such as detergent residue and many

different soil contaminants removed from the carpet you

have cleaned. These materials must be processed

before they are safe to re-enter our streams, rivers and

reservoirs.

AS PER FEDERAL, STATE AND LOCAL LAWS, DO

NOT DISPOSE OF WASTE WATER INTO STORM

DRAINS, GUTTERS, STREAMS, RESERVOIRS, ETC.

CLEANING SOLUTIONS & CLEANING

Your Cleanco Compact has been designed with the

latest technology to produce the highest quality cleaning

results possible. However it is only one of many tools of

the carpet cleaning trade, and can produce only as good

as the person operating it. There are no short cuts to

quality. It takes time, cleaning knowledge, and the

proper use of quality cleaning solutions.

Cleanco recommends Esteam Cleaning Systems brand

name for use in your Cleanco Compact. Also be sure to

follow directions of all cleaning solutions, to obtain

quality results and for safety. The improper use of

cleaning solutions in your Cleanco Compact can cause

serious damage to the plumbing system, high-pressure

pump, and heat exchangers. (Cleanco does not

recommend running products through your unit such as

solvents, or grease removers with a high concentration

of solvents).

Cleanco endorses the IICRC Standards for Carpet

Cleaning, which outlines proper cleaning procedures for

all types of carpet and all kinds of cleaning systems. We

encourage Cleanco owners to acquire a copy of these

standards from your distributor and make yourself

familiar with them. In brief, the standards specify that all

carpet must be dry vacuumed, preconditioned, rinsed,

and dried, in order to be properly cleaned.

CLEANING WAND PROCEDURE

To have a quality cleaning result, correct wand

movement is of the utmost importance. Failure to take

time and extra care can result in an unhappy client.

Always move the cleaning wand in a smooth forward

and backward motion. Apply slight pressure on the

forward stroke while injecting cleaning solution onto the

carpet. Then on the backstroke towards yourself again

apply slight pressure on the wand and inject and vacuum

cleaning solution. Continue this method over-lapping

each forward and backstroke, for about a three to four

foot square area. Once the three square foot area has

been completed, return back over the same area-

utilizing vacuum only. Moving across then clean and

vacuum the next three to four square feet and again

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

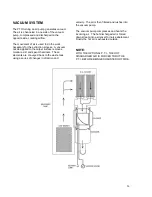

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...