O

SPINDLE SPEEDS

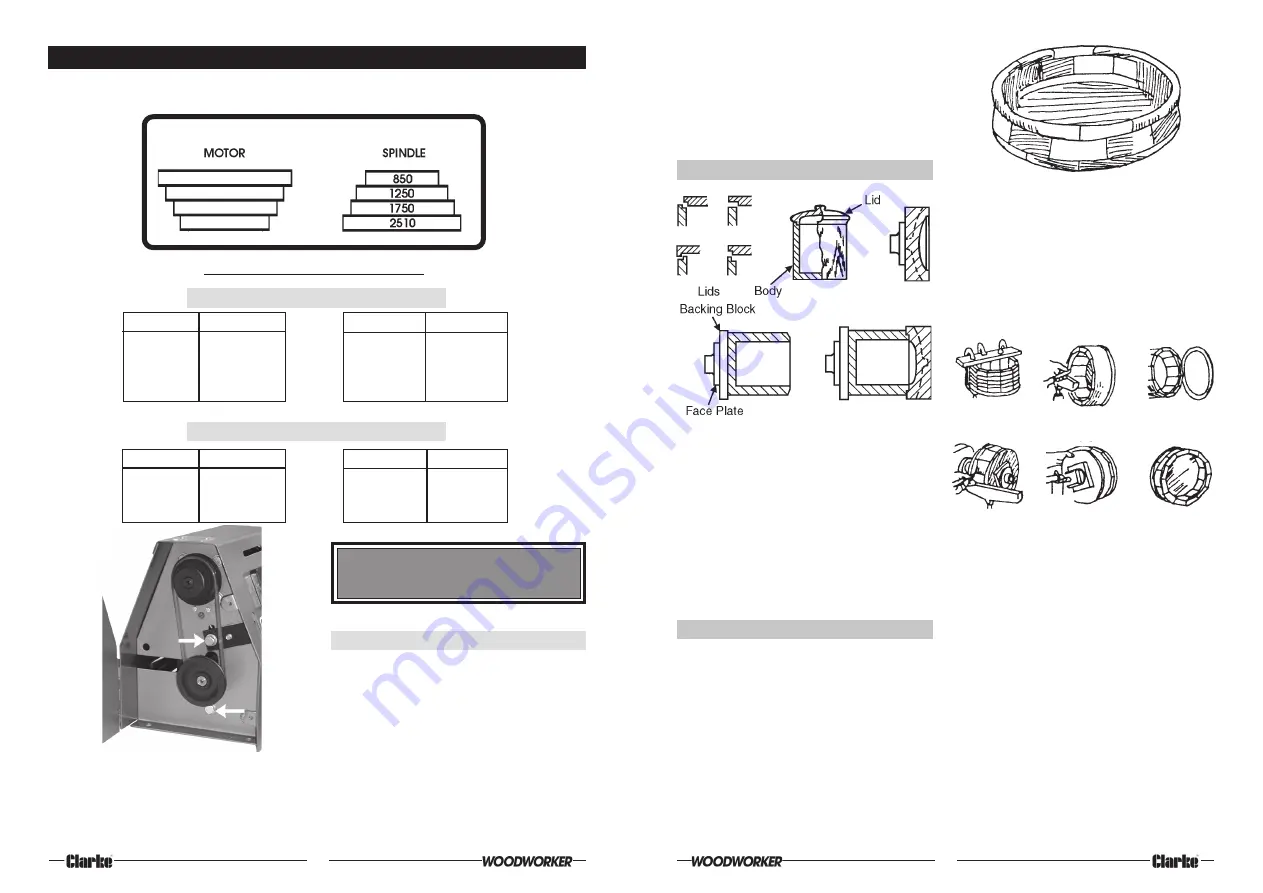

A chart showing spindle speeds and recommended turning speeds is mounted on the Head cowl

and for convenience, is duplicated as follows:

CAUTION : MAKE SURE THE POWER CORD IS

REMOVED FROM THE OUTLET BEFORE

ATTEMPTING TO CHANGE THE BELT POSITION.

Changing speeds

1.

Undo the two screws securing the Pulley

Access Panel.

2.

Slacken the two Motor securing bolts -

arrowed in Fig. 3.

3.

Pull down on the Belt Tension Lever to

remove belt tension.

4.

Move belt to appropriate pulley.

5.

Pull up on Belt Tension Lever to tension belt.

It should be firm - 1/2” total movement at

the middle of the run.

6.

Retighten Motor securing bolts and replace

Pulley Access Cover.

8

SPINDLE SPEEDS

Fig. 3

RECOMMENDED GENERAL SPEEDS

SPINDLE TURNING

SQUARE

LENGTH

ROUGHING

FINISHING

1” (25mm)

12” (305mm)

1750

2510

2” (50mm)

16” (406mm)

1250

2510

3” (75mm)

20” (508mm)

850

2510

4” (100mm)

20” (508mm)

850

2510

DIAMETER

THICKNESS

ROUGHING

FINISHING

9” (228mm)

4” (100mm)Max.

850

2510

8” (205mm)

4” (100mm)Max.

1250

2510

6” (150mm)

4” (100mm)Max.

1750

2510

FACE PLATE TURNING

Fig.3 shows the belt positioned on the second

step from the outside edge of the pulley. This

produces a spindle speed of 1250 RPM. (Refer

to the chart above).

If you wish to run at a higher speed, say 2510

RPM, you must shift the belt inwards, 2 steps.

the ball is constantly shifted, never more than

1/8 turn and always with a definite pattern. Since

turning between centres makes the work a

perfect sphere across the grain, the ball must

be mounted in the chuck so that the first

scraping cuts will round it up in the opposite

direction .

6. TURNED BOXES

To make the 12-piece bowl, a board about

22x76x760mm, is cut into pieces about 65mm

long, the saw blade being tilted 15° and the

board being turned alternatively face up and

face down to make the successive cuts. These

12 pieces glued together and clamped by

wrapping the assembly with wire. When dry the

rim thus formed is glued to a temporary circular

backing which is mounted on the large

faceplate.

Turned boxes involve deep recessing together

with a special system of working the lid and body

of the box together as one unit. The inside of

the lid is turned first. Next, the inside of the body

is turned. A careful check must be made when

turning the body portion so that the lid will be a

tight press fit. The lid is then pressed on to the

body and the outer circumference and face of

the lid, together with the outer circumference

of the body, are turned all at one time. This

insures accurate matching of the two pieces.

After the work is complete, the tight fit of the lid

can be relieved by sanding the lip of the body.

7. SEGMENTED TURNINGS

Segmented turnings and boxes can be

extremely attractive and this method of

preparing wood stock is more economical than

the use of a large stock piece.

For some types of work, segmenting is the only

practical method because a block (if

obtainable), would be so large that it would be

very likely to warp.

The bowl illustrated in fig. 51 requires 12 segment

pieces for the sides. Bowls can be worked with

6 or 8 pieces if desired.

A recess of the largest possible diameter, and

about 22mm deep, is turned in the open end of

the rim. The rim is removed from the lathe, and

stock for the bottom is mounted in its place on

a second faceplate. This is turned to size and a

rim about 3mm deep is turned to exactly fit the

recess prepared in the rim. The rim is then fitted

over the bottom and glued, making a drum

shape with a faceplate at each end. This drum

is cut completely in two, at a point about 22mm

above the bottom, completing the cut with a

hand saw. Both parts of the cut surface are

faced off square and smooth, then reglued

together, breaking the joints exactly half and

half. The cutting and regluing process is

repeated with a section about 32mm wide.

After this, the temporary backing block is cut

off, leaving the bowl as shown in the final

illustration. From this point on the work is simply

a matter of turning down the bowl to any desired

shape.

25

Fig. 52

Fig. 51

Fig. 50