O

ELECTRICAL CONNECTIONS

Connect the mains lead to a standard 230 volt (50Hz) electrical supply using a 13 amp BS1363 plug

fitted with a 13 amp fuse. or a suitably fused isolator switch.

WARNING : THIS APPLIANCE MUST BE EARTHED.

IMPORTANT : The wires in the mains lead are coloured in accordance with the following code :

Green & Yellow

-

Earth

Blue

-

Neutral

Brown

-

Live

As the colours of the flexible cord of this appliance may not correspond with the coloured markings

identifying terminals in your plug, proceed as follows :-

Connect GREEN & YELLOW coloured cord to plug terminal marked with a letter “E” or Earth

symbol ‘ ’ or coloured GREEN or GREEN & YELLOW.

Connect BROWN coloured cord to plug terminal marked letter “L” or coloured RED.

Connect BLUE coloured cord to plug terminal marked letter “N” or coloured BLACK.

We recommend that this unit is fitted with a Residual Current Device (RCD)

f this appliance is fitted with a plug which is moulded onto the electric cable (i.e. non-rewirable)

please note:

1.

The plug must be thrown away if it is cut from the electric cable. There is a danger of electric

shock if it is subsequently inserted into a socket outlet.

2.

Never use the plug without the fuse cover fitted.

3.

Should you wish to replace a detachable fuse carrier, ensure that the correct replacement is

used (as indicated by marking or colour code).

4.

Replacement fuse covers can be obtained from your local dealer or most electrical stockists.

5.

The fuse in the plug must be replaced with one of the same rating (13 amps) and this

replacement must be ASTA approved to BS1362.

We recommend that this machine is connected to the mains supply through a Residual Current

Device (RCD).

If in doubt, consult a qualified electrician. Do not attempt any electrical repairs yourself.

FUSE RATING

The fuse in the plug for this appliance must be rated at

13 amps

MOTOR SPECIFICATIONS

The four speed pulley system of this lathe is designed to use a 1725 RPM, 370W motor. Rotation is

clockwise as viewed from the pulley end of the shaft. It is wired for 230 Volt, 50Hz.

Caution: Do not any other type of motor as their use may be hazardous

.

6

The machines’ ON and OFF buttons are marked “I” for ON and “O” for OFF.

Should the power fail whilst the machine is in use, the NO VOLT RELAY will operate. This is a safety

feature which prevents the machine from starting up automatically when the power is restored. It

will be necessary to press the ON button to continue operations.

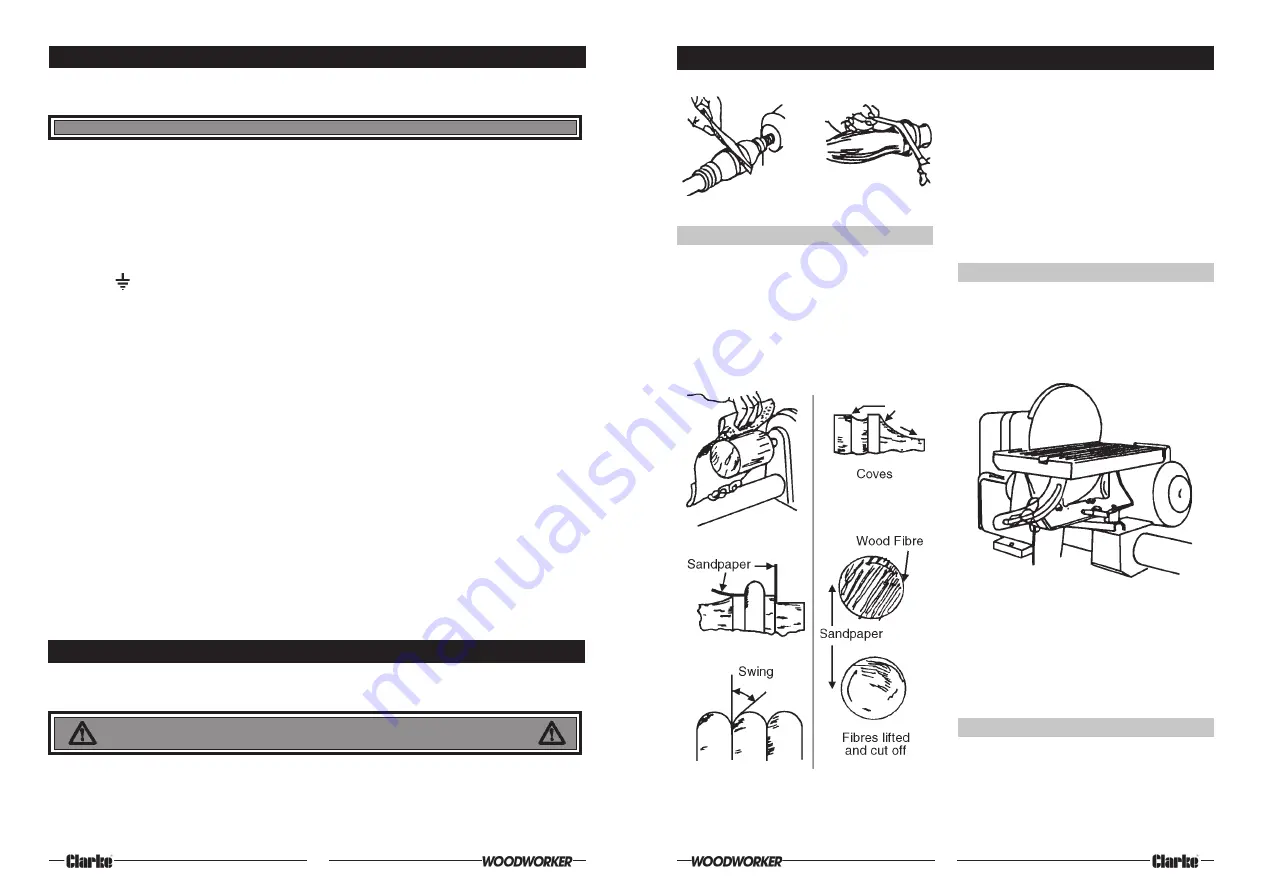

The application of the sandpaper strip is shown

in fig. 57. Care must be exercised in order to

prevent dubbing the corners of beads, shoulders

etc. It is good practice to finish sanding with

the work in reverse rotation. This is particularly

true when sanding basswood, white pine and

mahogany. These woods are hard to sand

clean since sanding packs the surface fuzz

down to the wood. Sanding very lightly, and

not too long with the lathe reversed, will lift the

fibres and cut them off cleanly.

2.

USE OF SANDING DISCS

A fully adjustable sanding table adds to the

scope and convenience of sanding operations.

Sanding is always done on the down travel side

of the wheel working on the other side would

kick the work upwards. Either second or third

speed can be used.

SANDING, BUFFING AND POLISHING

1. USING THE LATHE TO SAND TURNINGS

Turnings should be sanded with the lathe running

in second lowest speed. A large sheet of

sandpaper is useful for smoothing cylinders. All

other sanding operations are done with a

narrow strip of abrasive paper. The best finishing

grit is 3/0 for soft wood, 4/0 for hard woods. Worn

2/0 paper is often used, and is the equivalent of

3/0 or 4/0 new paper.

The sanding disc is a metal plate with a threaded

shank which fits the end of the lathe spindle.

Abrasive paper is glued to the machined

surface of the plate by means of a quick drying

cement supplied for this purpose. Abrasive discs

can be purchased or cut from the standard sizes

of abrasive paper.

3.

USE OF SANDING DRUMS

Standard sanding drums are usually rubber

cylinders which can be expanded to hold an

abrasive sleeve in place. Similar cylinders turned

on the lathe and covered with abrasive paper

27

Fig.58

Fig. 57

Fig. 56