O

9. USING WOOD RASPS AND FILES

10.2 Finish Cutting

A wood rasp will remove stock quickly when held

against the revolving workpiece. Care should

be taken to support the rasp firmly against the

tool rest however, as it can tear the hands

painfully if caught by a rough edge of the

workpiece and kicked back. The rasp will leave

a very rough finish.

Finer finishes (similar to those produced by

scraping), can be obtained by using files in the

same manner. Various shape files can be used

for shaping vees, beads, coves etc. If pressed

into the wood too hard, however, a file can burn

the workpiece surface. Keep the file clean to

keep it cutting uniformly. Files work best on hard

woods.

10. HAND POSITIONS

When handling a chisel, the hand takes a

natural position, being nearer or farther from the

end depending upon the amount of leverage

required. The position of the tool rest hand is a

matter of individual liking, but there are three

generally accepted positions, each best for

certain types of operations.

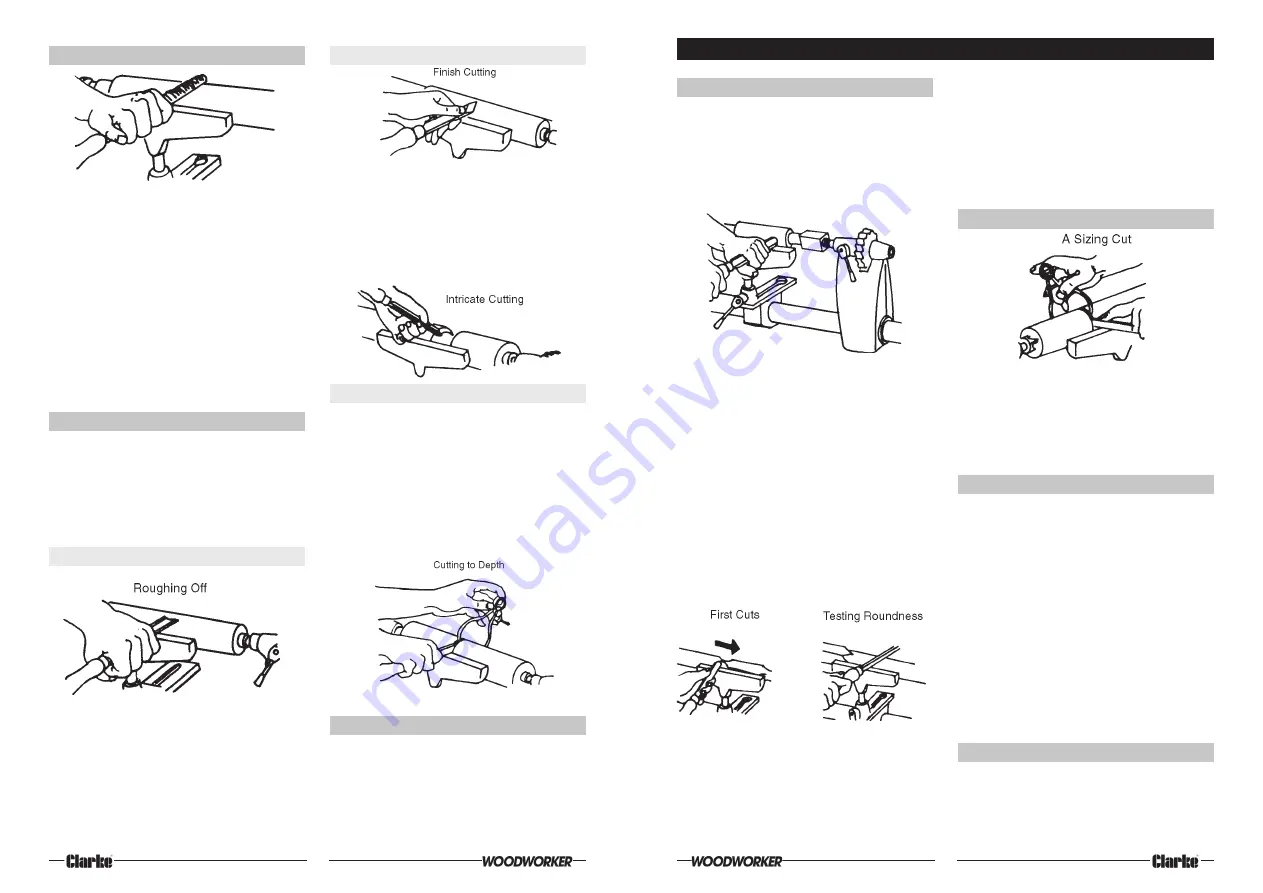

10.1 Roughing Off

Roughing off and other heavy work requires a

firm grip and solid positioning of the chisel

against the rest. This is best obtained by the tool

rest hand position as illustrated. The wrist is

dropped down so that the heel of the hand

below the little finger acts as a sliding guide

against the rest. The handle hand controls chisel

position.

Finish cutting requires more control with less force

and is better done with the palm of the tool rest

hand turned up. The wrist is still held down, and

the side of the index finger acts as a guide along

the rest. In this position, control of the chisel is

shared by both hands, the fingers of the tool rest

hand being free to assist in positioning the tool.

10.3 Intricate Cutting

Intricate, delicate cutting requires extreme

control, with practically no force. This is best

accomplished by guiding the chisel with the

fingers of the tool rest hand. The hand is held

palm up, with the wrist high, and the little finger

placed against the rest to steady the hand. The

chisel does not touch the rest and the handle

hand is completely secondary to the tool rest

hand.

The first and second positions are equally good

for scraping operations, but the third position is

never used for scraping.

11. CUTTING TO DEPTH

Many scraping operations and cutting to depth

with the parting tool can be easily done with

one hand. The chisel is grasped firmly with the

index finger on top, to press it down against the

rest, and is thrust straight into the work. Holding

the tool thus leaves the other hand free to hold

a pattern , callipers etc., to check work progress.

16

Fig. 21

Fig. 23

Fig. 20

Fig. 24

Fig. 22

MAKING STANDARD CUTS

1. THE ROUGHING OFF-CUT

Reducing a square or odd shaped workpiece

down to a cylinder of approximate size for finish

turning is called roughing-off. Faceplate

turnings and large diameter spindles should first

be partly reduced by sawing , but small spindles

are easily turned down entirely with the large

(3/4”) gouge.

Start the first cut about 50mm from tailstock and

then run it toward the tailstock and off the end

of the workpiece.

Next, start another cut 50mm nearer the

headstock and run it also toward tailstock to

merge with first cut.

Continue in this manner until 50mm to 100mm

from the headstock end, then reverse the

direction of tool travel and work one or two cuts

in succession toward the headstock and off this

end of the workpiece.

Never start a cut directly at the end. If the chisel

catches the end, it will damage the workpiece.

Never take long cuts while corners remain on

the work, as this tends to tear long slivers from

the corners.

The first series of cuts should not be too deep. It

is better to partially reduce the work to a cylinder

along its complete length, then start a second

series of cuts to reduce it to a cylinder. Once a

cylinder has been formed, step the lathe up to

its next fastest speed. Further reductions in size

can now be carried out by cutting as deeply

17

as desired at any spot along the work.

At this stage long cuts from the centre of either

end can also be taken. Roughing-off generally

is continued until the cylinder is approximately

3mm larger than the desired finished size.

Roundness can be tested by laying the gouge

on top of the work - it will not ride up and down

when cylinder is perfectly round.

2. ROUGH-CUTTING TO SIZE

Fig. 26

Fig. 27

Fig. 25

The roughing-off cut can be made to accurately

size the cylinder to a given diameter.

Another method is to make a number of sizing

cuts at intervals along the work, then use the

gouge to reduce the whole cylinder down to

the diameter indicated by these cuts.

3. MAKING SIZING CUTS

Sizing cuts are useful to establish approximate

finish-size diameters at various points along a

workpiece. The work can then be turned down

to the diameters indicated and be ready for

finishing.

Diameters for sizing cuts should be planned to

be about 3mm greater than the desired finished

diameters.

A sizing cut is made with the parting tool.

Hold the tool in one hand and use the other

hand to hold an outside calliper, preset to the

desired sizing-cut diameter.

As the cut nears completion, lower the chisel

point more and more into a scraping position.

When the callipers slip over the workpiece at

the cut, the cut is finished.

4. SMOOTHING A CYLINDER

The final 3mm can be removed in two ways.

Either use the 3/4” skew, working from the centre

toward both ends and taking lighter and lighter

cuts until finished.