O

Better chisels have handles approximately 10"

(250mm) long, to provide plenty of grip and

leverage. Sharp tools are essential for clean,

easy work. Buy tools that will take and hold keen

edges.

An 8 piece chisel set is available from your

CLARKE dealer, part no. 6500649

2. THEORY OF TURNING

There are two classes of chisel; these are :

a.

Chisels intended primarily for cutting, and

b.

Chisels used only for scraping.

The cutting chisels are the gouge, skew and

parting tool. These are most commonly used.

They are sharpened to a razor edge by honing

on both sides.

The scraping chisels are the flat nose, round nose

and spear point. These are not honed on the

flat sides, the wire edges produced by grinding

are left on to aid in the scraping process.

must faster, especially the razor sharp cutting

chisels.

Cutting is faster than scraping and produces a

smoother finish which requires less sanding.

However, it is far more difficult to master.

Scraping, on the other hand, is far more precise

and easier to control.

12

USING WOODWORKING CHISELS

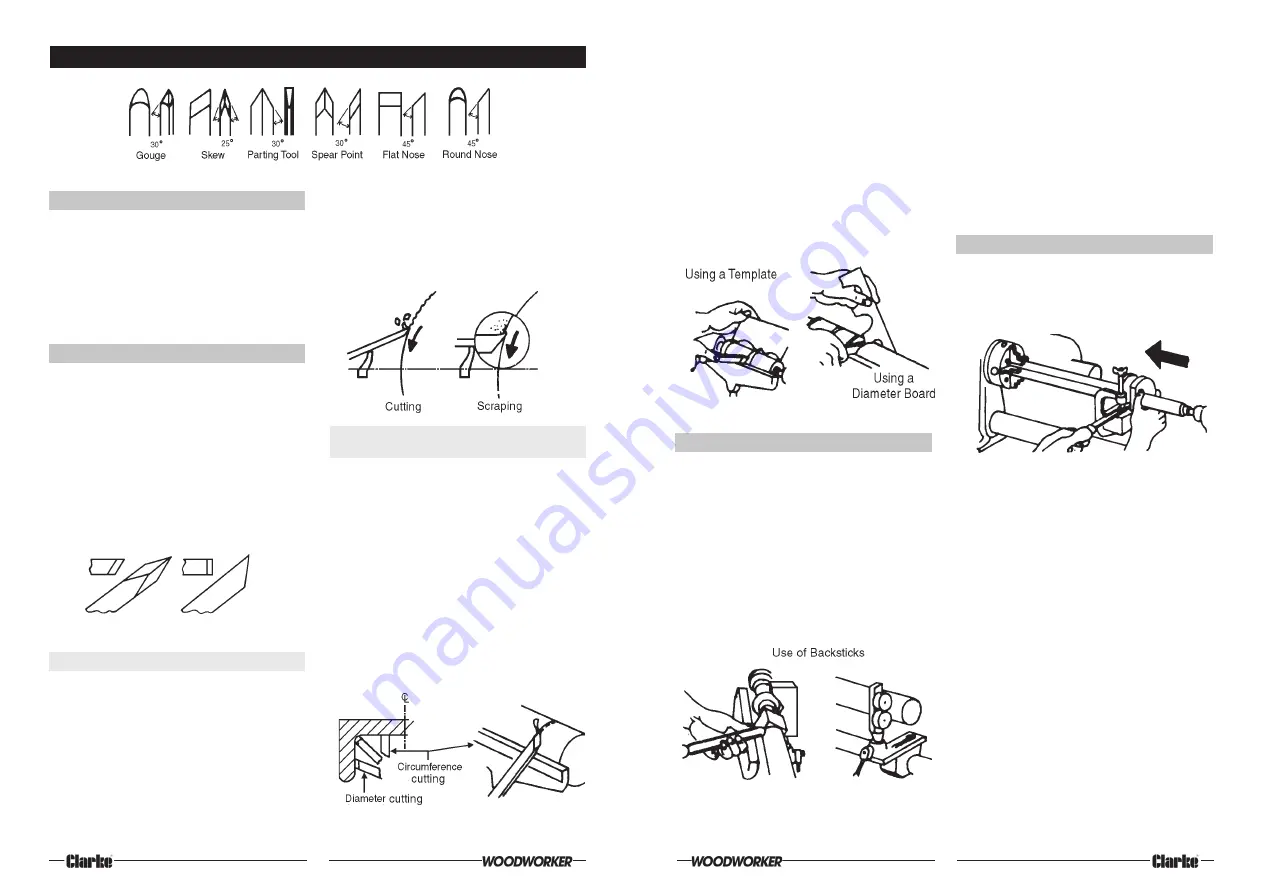

THE SIX MOST COMMONLY USED CHISEL TYPES

2.1 Cutting and Scraping

To cut, the chisel is held so that the sharp edge

actually digs into the revolving work to peel off

a shaving.

To scrape, the chisel is held at a right angle to

the work surface as shown in fig. 12, and

removes fine particles instead of shavings.

Many operations require that the cutting chisels

be used for scraping, but scraping chisels are

never used for cutting. Scraping dulls a chisel

Cutting Chisel Scraping Chisel

2.2 When You Can Cut and When You

Must Scrape.

There are two different types of cut to consider

when turning.

One is cutting at the circumference of the

workpiece (for example, turning down the outer

surface of a cylinder or the inner wall of a hollow

round box, as shown in fig. 13). In this approach

the surface being turned travels under the chisel

edge like an endless belt.

The second type is cutting at the diameter of a

workpiece (as when tur ning the face of

faceplate turning or the side of a large shoulder

on a spindle turning, as shown in fig. 13). In this

approach the surface being turned rotates like

a disc under the chisel edge. Sometimes the

approach will be a combination of both.

Fig. 10

Fig. 12

Fig. 11

Fig. 13

1. SELECTION OF CHISELS

3. LONG SPINDLES

A long turning can be worked in short sections,

with joints arranged to be at shoulders where

they will not be noticed.

Long thin work that is likely to whip while turning

should be supported at one or two places by a

backstick. This is easy to make. A simple one

consists of a short length of wood mounted

vertically in an extra tool rest, and notched so

that it can be used to support the spindle from

behind. An improved type which uses 2 roller

skate wheels to form the notch-size is shown.

21

turning. The first finished turning can also be used

as a template.

Attach the template to a board, then mount

the board behind the lathe on hinges, so that

the template can be moved down to touch the

workpiece and allow you to closely observe

progress of your work.

If a great many turnings are being produced, a

diameter board will save the time used for

resetting callipers. This is simply a thin board

along the edge of which a number of

semicircular cuts have been prepared to

represent all the various calliper settings required

for measuring the sizing cuts. Each semicircular

cut is held against the workpiece instead of using

the callipers.

Position the backstick against a pre-turned

portion near the centre of the spindle, this

portion being at least 3mm over finish size to

allow for later removal of any marks made upon

it.

Operate lathe at a slower speed than normal.

Lubricate the workpiece at point of contact with

the backstick, using beeswax (preferably), or

grease.

After completing the turning, remove the

backstick and finish off the original point of

contact. Sand off any slight burns remaining on

workpiece.

4. CUTTING DOWELS

Dowels of any size can be turned quickly with

the simple jig shown. If the stock is prepared as

a split or quartered turning, half round and

quarter rounds will be produced.

The jig uses a 1/2” gouge as the cutting tool and

will produce dowels up to 11mm diameter. Make

the jig from suitable hardwood stock as shown.

The hole through the jig must be large enough

at the side, to the left of the gouge, to allow

passage of the square stock. At the right of the

gouge this hole must be just the diameter of the

finished dowel. Make the jig so you can hold

and guide it by hand.

To start, centre the stock as you would for a

spindle turning and turn down about 50mm at

the right end to desired size.

Then remove the stock, place your jig over the

turned end, with turned portion through the

smaller jig hole, and re-centre the stock on the

lathe.

Hold the jig firmly and start the lathe. Push the

jig slowly right to left along the stock until the

whole dowel is complete.

Fig. 38

Fig.39

Fig. 37