INST No INE -403-0P0

−

35

−

8.9 Measurement

(1) When the correction by sample temperature ON (enable) is selected and one calibration

curve number in a group is set, the calibration curve number changes automatically

corresponding to sample temperature.

For example, when the sample temperature Ts fulfills the following expression, the

calibration curve number becomes “i”.

T1

…..

Ti

Ts < Ti + 1

…..

T10

(2) However, the measured value Y is not the measur ed value T

1

on the calibration curve No.

“i”. The measured value Y becomes the following value interpolated from the measured

value Y

i

and the measured value Y

i+1

on the calibration curve No. “i+1”.

(3) When the sample temperature Ts is lower than the sample temperature of the first

calibration curve number in the group or when it is higher than the sample temperature of

the last calibration curve number, the following error display appears.

However, the calibration curve, of which sample temperature is set as 999.9, is ignored.

* For the sample temperature lower than the sample temperature of the first calibration

curve number in the group

Er15 (Sample temperature too low)

* For the sample temperature higher than the sample temperature of the first calibration

curve number in the group

Er14 (Sample temperature too high)

8.10 Display of sample temperature Ts

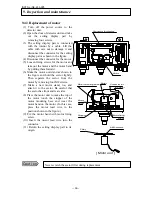

8.10.1 Display at the detector unit

(1) Set the calibration curve number to 0. CH 0 ENT

(2) For canceling of the sample temperature display SEL for 2 seconds or CH 2 for seconds

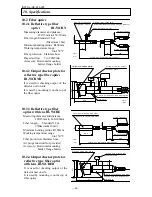

8.10.2 Display at the setting display unit

(1) Set the calibration curve number to 0. CH 0 ENT

(2) For displaying the sample temperature display MODE 2 0 ENT

(3) For canceling of the sample temperature display SEL for 2 seconds or CH for 2 seconds

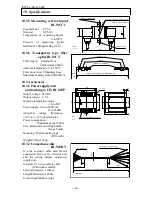

9.1 Periodical inspection

The following inspection is required periodically.

(1) Cleaning of tip of fiber optics (for reflective type fiber optics)

Keep the tip of fiber optics clean.

If any dirt or dust is noticed, remove it with gauze etc. If the gauze is dipped in alcohol, it

is more effective.

(2) Disassemble cleaning of measuring cell (for transparent type fiber optics)

Regular cleaning of the cover glass in a liquid-contacting part of the measuring cell is

required by disassembling the measuring cell.

(3) Installation

Check the detector unit is installed firmly.

(4) Wiring

Check the wirings to the terminals of the detector unit, the setting display unit and other

instruments are connected completely.

(5) Calibration

Regular calibration one in 3 months is required.

8.

Correction function by sample temperature from external input

9. Inspection and maintenance