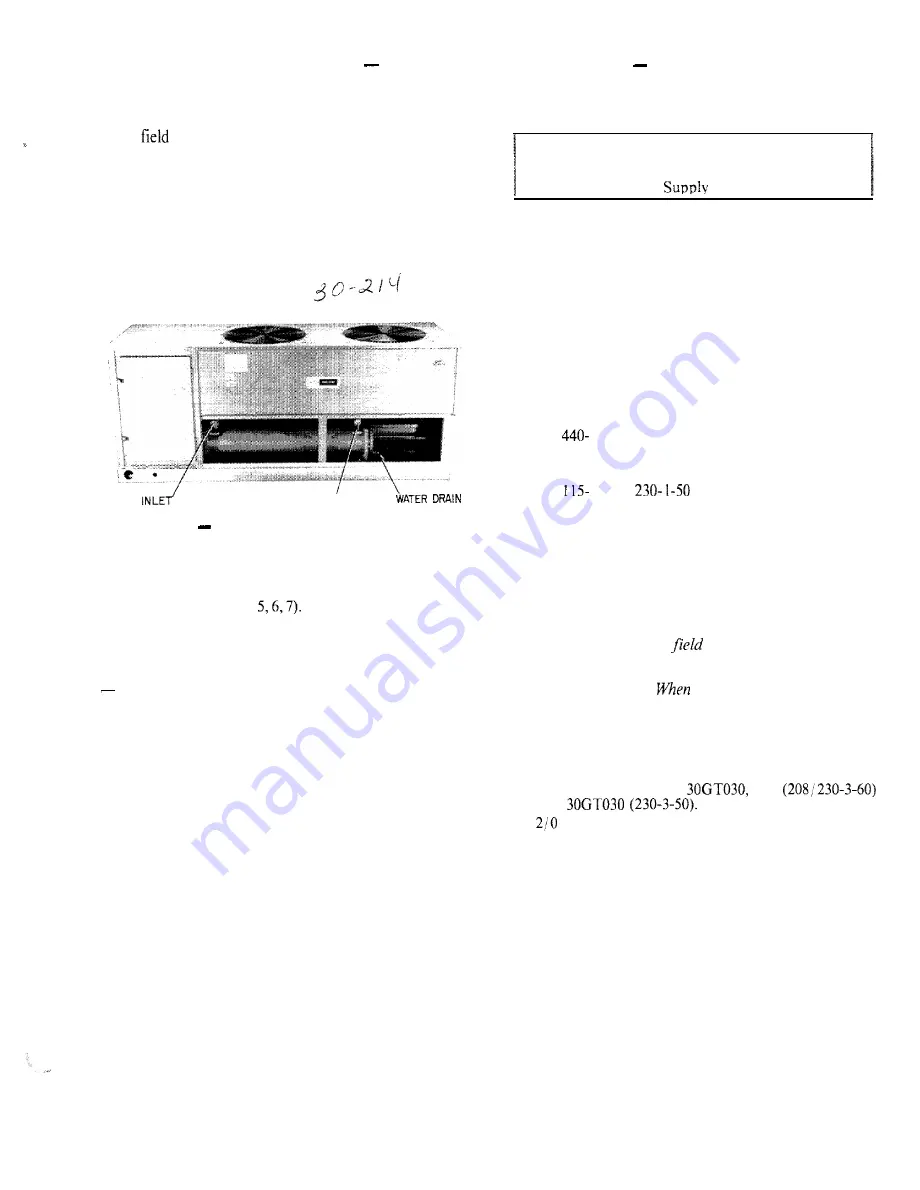

Chilled Water and Drain Piping

Facing the

cooler side of the unit, the return water connection is on

the left and the leaving water connection is on the right.

See Fig. 4, 5, 6, 7. A means of venting air from the high

point of the field-installed piping should be provided.

After

piping is complete, in area where piping is

exposed to low ambient temperatures (32F or below),

freeze-up protection is recommended using ethylene

glycol or electric heat tapes. Heat tapes should possess a

rating for area ambients and covered with a suitable

thickness of closed cell insulation. Route power for

heating tapes from a separate fused disconnect. Identify

disconnect as heat tape power source with warning that

power must not be turned off except when unit is being

serviced.

WATER

WATER OUTLET’

Fig. 4

Water Connection Locations

The cooler drain connection is at the opposite end from

the compressor (see Fig.

Insulate the drain piping,

similar to the chilled water piping, for at least one foot

(305 mm) from cooler.

PREPARATION FOR YEAR-ROUND OPERATION

If unit is on year-round operation, add sufficient

ethylene glycol to chilled water to prevent freezing under

operating ambient conditions. Consult local water

authority on characteristics of area water and add a

recommended inhibitor to the chilled water.

PREPARATION FOR WINTER SI-IIJTDOWN

Do

not shut off control power disconnect during off-season

shutdown.

At end of cooling season, drain water from

system. Replace drain plug and put 2 gallons (8 liters) of

ethylene glycol in cooler to prevent freezing of residual

water. Remove plug on top of leaving chilled water

nozzle to add glycol. At beginning of next chilling

season, refill cooler and add recommended inhibitor.

Power Supply

Electrical characteristics of avail-

able power supply must agree with unit nameplate rating.

Supply voltage must be within limits shown in Table 2.

IMPORTANT: Operating unit on improper supply

voltage, or with excessive phase imbalance, con-

stitutes abuse and may affect Carrier warranty. See

Unbalanced 3-Phase

Voltage, page 4.

Power Wiring

All power wiring must comply with

applicable local and national codes. Install field-supplied

branch circuit fused disconnect(s) per NEC (National

Electrical Code, U.S.) of a type that can be locked OFF

or OPEN. Disconnect(s) must be within sight from and

readily accessible from unit in compliance with NEC

Article

14.

GENERAL WIRING NOTES

1.

2.

3.

4.

5.

6.

The

l-60 or

control circuit power must be

from a separate source, through a field-supplied fused

disconnect rated at 7 amps.

Crankcase and cooler heaters are wired in the control

circuit so they are always operable as long as control

power supply disconnect is on, even if any safety

device is open or unit stop-start switch is off. Heaters

are wired ahead of stop-start switch. They are pro-

tected by 7-amp fuse in control power supply

disconnect.

The control circuit

supply disconnect should

never be open except when unit is being serviced or is

to be down for aprotongedperiod in which case cooler

should be drained.

operation is resumed, crank-

case heater should be energized for 24 hours before

start-up.

Power entry is at one end only.

Maximum field wire sizes allowed by lugs on terminal

block are:

350

MCM for Models

035

and

AWG for all other models.

Terminals for field power supply are suitable for

copper, copper-clad aluminum or aluminum con-

ductors. Insulation must be rated 167 F (75 C)

minimum.