Fixing System

Outline

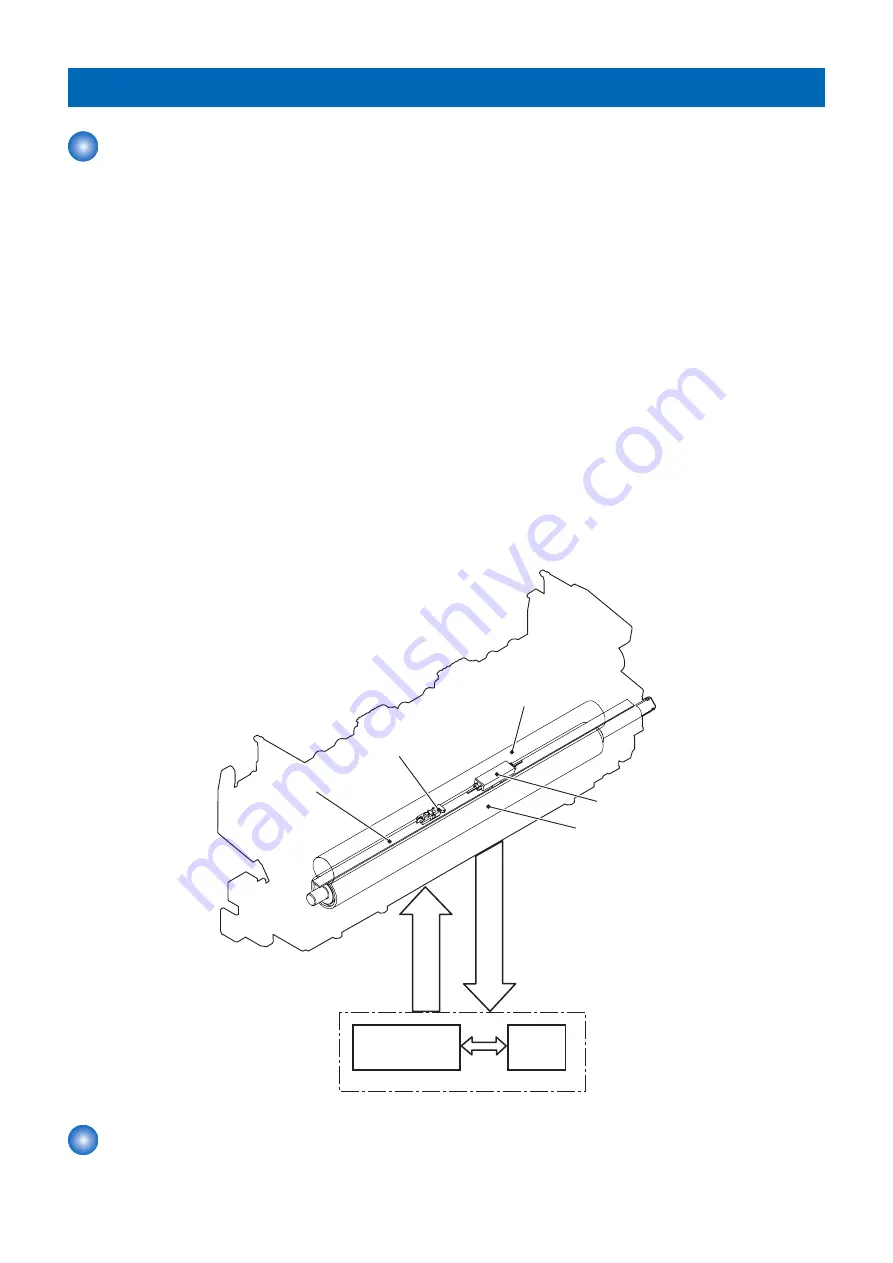

The fixing/delivery unit fixes the toner onto a print paper and delivers it to the delivery tray.

The operation of the fixing/delivery unit is explained in the following.

1. The print paper fed from the pick-up/feed unit is fused the toner by the fixing film and the pressure roller.

2. The print paper delivered from the fixing unit is delivered to the face-down delivery tray or the face-up delivery slot. When

the engine controller detects that the heater temperature reaches 50 deg C after the last rotation is completed, it drives the

main motor for 50 msec. and dislocates the nip part. This prevents the toner adhering to the pressure roller.

The fixing unit of this printer utilizes the on-demand fixing method. It is structured as shown below.

• Heater:

This fixing unit incorporates one heater.

Fixing heater (H1): To heat the fixing film (ceramic heater)

• Thermistor:

This fixing unit incorporates one thermistor.

Thermistor (TH1): Sit almost at the center of the fixing film. (contact type)

To control the temperature of the fixing film

• Thermal switch:

Thermoswitch (TP1): Sit almost at the center of the fixing film (contact type)

If the temperature of the heater rises abnormally high, the contact gets broken and cuts off the AC voltage supply to the

fixing heater to interrupt the power supply to the heater.

The temperature control of the fixing unit incorporated as above is operated by the fixing temperature control circuit according to

the command from the CPU (IC201) on the DC controller.

The followings describe the each circuit and function of the temperature control of the fixing unit.

Fixing film

Fixing unit

Thermistor

Fixing heater

Thermoswitch

Pressure roller

F

IXI

N

G

T

EMPER

A

T

U

R

E

D

ET

EC

T

IO

N

si

g

n

a

l

Engine controller PCB

CPU

F

IXN

G

H

EAT

ER

C

O

N

T

R

O

L

si

g

n

a

l

Fixing heater

control circuit

Fixing control circuit

The fixing control circuit controls the temperature in the fixing unit. The printer uses an on-demand fixing method.

2. Technology

22