Chapter 7

7-209

7.11.26

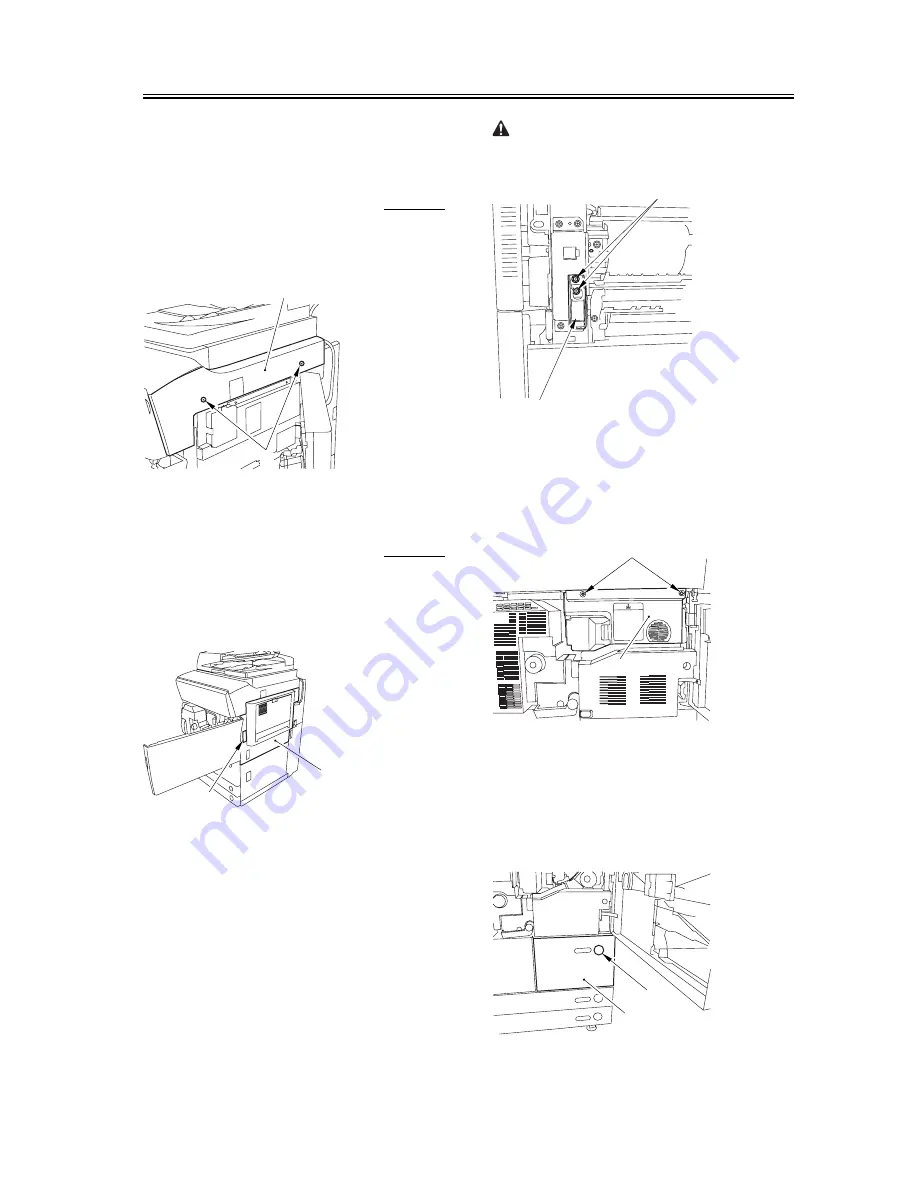

ITB Cleaner End Scraper

7.11.26.1

Removing the Right

Cover (upper)

0005-9396

1) Remove the 2 screws [1], and detach the right cover

(upper) [2].

F-7-746

7.11.26.2

Releasing the Front

Cover

0005-9397

1) Open the front cover.

2) While pulling on the grip [1], fully open the manual

feed cover [2] to the front.

F-7-747

If a side paper deck exists, remove the 2 screws [1]

and the latch plate (front)

F-7-748

3) Slide out the fixing/feeding assembly

4) Remove the 2 screws [1], and detach the process

unit cover [2].

F-7-749

5) Push in the fixing/feeding assembly, and set the

lever in place.

6) Push the release button [1] of the right deck, and

slide out the right deck [2].

F-7-750

[1]

[2]

[1]

[2]

[2]

[1]

[2]

[1]

[1]

[2]

Summary of Contents for iR C6800 Series

Page 1: ...Apr 6 2004 Service Manual iR C6800 Series iR C6800C ...

Page 2: ......

Page 6: ......

Page 21: ...Chapter 1 Introduction ...

Page 22: ......

Page 24: ......

Page 55: ...Chapter 2 Installation ...

Page 56: ......

Page 115: ...Chapter 3 Basic Operation ...

Page 116: ......

Page 118: ......

Page 129: ...Chapter 4 Main Controller ...

Page 130: ......

Page 178: ...Chapter 4 4 46 ...

Page 179: ...Chapter 5 Original Exposure System ...

Page 180: ......

Page 234: ...Chapter 5 5 52 ...

Page 235: ...Chapter 6 Laser Exposure ...

Page 236: ......

Page 238: ......

Page 257: ...Chapter 7 Image Formation ...

Page 258: ......

Page 562: ...Chapter 7 7 296 ...

Page 563: ...Chapter 8 Pickup Feeding System ...

Page 564: ......

Page 614: ...Chapter 8 8 46 F 8 49 10 9 12 11 5 5 4 4 3 5 1 2 1 2 3 1 2 3 4 1 2 3 4 5 ...

Page 616: ...Chapter 8 8 48 F 8 51 2 1 3 3 3 2 1 1 2 1 2 3 5 6 7 8 ...

Page 660: ...Chapter 8 8 92 ...

Page 661: ...Chapter 9 Fixing System ...

Page 662: ......

Page 728: ...Chapter 9 9 64 ...

Page 729: ...Chapter 10 Externals and Controls ...

Page 730: ......

Page 734: ...Contents ...

Page 742: ...Chapter 10 10 8 F 10 2 FM12 FM11 FM1 FM2 FM4 FM3 FM6 FM7 FM9 FM8 FM5 FM13 FM14 FM10 ...

Page 787: ...Chapter 11 Maintenance and Inspection ...

Page 788: ......

Page 790: ......

Page 815: ...Chapter 12 Standards and Adjustments ...

Page 816: ......

Page 868: ...Chapter 12 12 50 ...

Page 869: ...Chapter 13 Correcting Faulty Images ...

Page 870: ......

Page 882: ...Chapter 13 13 10 13 3 Troubleshooting ...

Page 898: ...Chapter 13 13 26 Image Sample F 13 13 ...

Page 900: ...Chapter 13 13 28 Image Sample F 13 15 ...

Page 929: ...Chapter 13 13 57 Image Sample F 13 45 ...

Page 932: ...Chapter 13 13 60 Image Sample image of a specific color is too light F 13 47 ...

Page 933: ...Chapter 13 13 61 image of a specific color is too dark F 13 48 ...

Page 934: ...Chapter 13 13 62 image is too light overall F 13 49 ...

Page 966: ...Chapter 13 13 94 F 13 70 PS65 PS38 PS39 PS46 PS44 PS45 PS52 PS53 PS58 PS59 PS37 ...

Page 968: ...Chapter 13 13 96 F 13 71 SW14 SW15 SW12 SW11 SW1 SW13 SW2 SW3 ...

Page 980: ...Chapter 13 13 108 ...

Page 981: ...Chapter 14 Self Diagnosis ...

Page 982: ......

Page 1051: ...Chapter 15 Service Mode ...

Page 1052: ......

Page 1302: ...Chapter 15 15 238 ...

Page 1303: ...Chapter 16 Upgrading ...

Page 1304: ......

Page 1306: ......

Page 1395: ...Chapter 17 Service Tools ...

Page 1396: ......

Page 1397: ...Contents Contents 17 1 Special Tools 17 1 17 2 Solvents and Oils 17 3 ...

Page 1398: ......

Page 1402: ...Chapter 17 17 4 ...

Page 1403: ...Apr 6 2004 ...

Page 1404: ......