Chapter 19

19-124

19.6 TEST (Test Print Mode)

19.6.1 COPIER

19.6.1.1 COPIER Table

1. PG

T-19-68

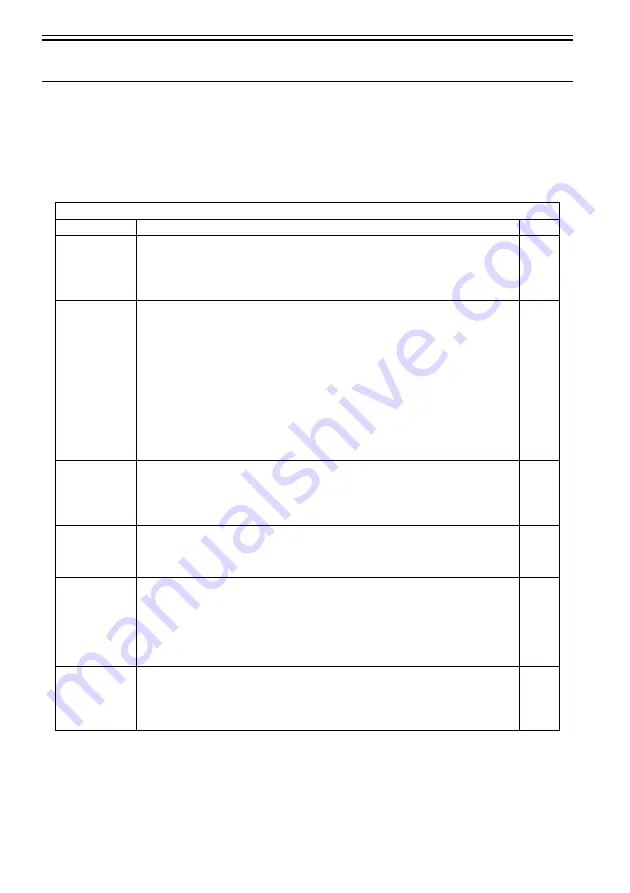

COPIER>TEST>PG

Sub item

Description

level.

TYPE

Performs test print when test print type number is entered and start key is turned ON. (This

setting must always be restored to 0 after making test print.)

Setting values

0: Normal print, 0 to 100

[Factory default/After RAM clear: 0]

1

TXPH

Used to set image mode during test print output.

Setting values

0: Text mode

1: Photo mode

2: Automatic mode

3: Text/photo/map mode

4: Photographic printing paper photo mode

5: Printed photo mode

6: Text/photo mode

7: Black and white text mode

Reference:

This setting is only valid for test prints.

[Factory default/After RAM clear: 0]

1

THRU

Used to select whether to use image compensation table during test print output.

Setting values

0: ON (Use)

1: OFF (Don't use)

[Factory default/After RAM clear: 0]

1

DENS-Y/M/C/K

Used to adjust density of each color for test prints (TYPE = 5).

Setting values

0 to 255: Increasing the value increases the density.

[Factory default/After RAM clear: 128]

1

COLOR-Y/M/C/

K

Used to set output of each color for each TYPE.

For example, to set single-color M output, set "COLOR-M = 1", and make the other

settings 0 (only single colors can be output).

Setting values

0: Don't output

1: Output

[Factory default/After RAM clear: 1]

1

F/M-SW

Set it to switch over full color and mono color during PG output.

Settings

0: full color output

1: mono color output

[Factory default/After RAM clear: 0]

1

Summary of Contents for Color imageRUNNER C4580

Page 22: ...Chapter 1 INTRODUCTION ...

Page 64: ...Chapter 2 INSTALLATION ...

Page 110: ...Chapter 3 BASIC OPERATION ...

Page 119: ...Chapter 4 BASIC OPERATIONS AS A PRINTER ...

Page 129: ...Chapter 5 MAIN CONTROLLER ...

Page 138: ...Chapter 5 5 8 F 5 8 CPU HDD ROM access to the program at time of execution ...

Page 165: ...Chapter 6 ORIGINAL EXPOSURE SYSTEM ...

Page 209: ...Chapter 7 IMAGE PROCESSING SYSTEM ...

Page 212: ...Chapter LASER EXPOSURE 8 ...

Page 239: ...Chapter 9 IMAGE FORMATION ...

Page 324: ...Chapter 10 PICKUP FEEDING SYSTEM ...

Page 435: ...Chapter 11 FIXING SYSTEM ...

Page 460: ...Chapter 11 11 23 F 11 13 SEN3 SEN2 SEN1 SEN2 SEN3 SEN1 SEN2 SEN3 SEN1 ...

Page 491: ...Chapter 12 EXTERNALS CONTROLS ...

Page 498: ...Chapter 12 12 5 F 12 2 FM1 FM7 FM9 FM2 FM13 FM14 FM12 FM11 FM10 FM5 FM3 FM4 FM8 FM6 ...

Page 512: ...Chapter 12 12 19 2 Remove the check mark from SNMP Status Enabled F 12 10 ...

Page 553: ...Chapter 13 MEAP ...

Page 557: ...Chapter 14 RDS ...

Page 569: ...Chapter 15 MAINTENANCE INSPECTION ...

Page 578: ...Chapter 16 STANDARDS ADJUSTMENTS ...

Page 597: ...Chapter 17 CORRECTING FAULTY IMAGES ...

Page 612: ...Chapter 17 17 14 F 17 7 PLG1 ELCB1 SP1 H4 H3 H2 H1 H1 H2 LA1 ...

Page 617: ...Chapter 18 SELF DIAGNOSIS ...

Page 644: ...Chapter 19 SERVICE MODE ...

Page 778: ...Chapter 20 UPGRADING ...

Page 823: ...Chapter 21 SERVICE TOOLS ...

Page 828: ...APPENDIX ...

Page 851: ......