12

single-pass, counter-flow, fire-tube design. Models 400

MBH throughout 850 MBH are designed to withstand 160

PSIG of operating pressure.

∆T HEAT EXCHANGER ALGORITHM

The Valiant FT Series 2 is constantly monitoring the inlet

and outlet water temperatures.

When the ∆T approaches

60°F the burner will modulate down to prevent tripping of

the high limit and to protect the heat exchanger against

thermal shock. This setting may be changed in the Valiant

FT Series 2 control.

LOW WATER TEMPERATURE SYSTEMS

In applications where the heating system requires supply

water temperatures below 110°F, connections may be

made directly to the Valiant FT Series II. At incoming

temperatures of 120°F or lower this appliance achieves

maximum efficiency. Inlet temperatures must not drop

below 40°F to prevent freezing.

2.4.6 Flow and pressure drop at a given

∆T

Table 8: Valiant-FT Series II Flow and Pressure Drops

vs

∆T

Input

KBtu/hr

Flow and Pressure Drop at given

∆T

20°F

30°F

40°F

GPM

∆P

GPM

∆P

GPM

∆P

400

39.6

4.2

26.4

2.8

19.8

3.0

500

49.5

4.3

33

3.9

24.7

3.9

600

59.4

5.7

39.6

4.5

29.7

3.0

725

71.7

5.8

47.8

3.6

35.9

4.7

850

84.1

6.1

56.1

3.9

42

3.8

Table 9: Valiant-FT Series II Minimum Flow

Model

400

500

600

725

850

US GPM

13.2

16.5

19.8

23.9

28.0

2.5

ELECTRICAL CONNECTIONS

2.5.1 Minimum Power Requirements

Table 10: Minimum Power Requirements

Model

Voltage

Requirement

Full Load

Amps

[Amperes]

Maximum

Over

Protection

[Amperes]

400

115VAC, 60Hz,

Single Phase

7

15

500

7

15

600

7

15

725

7

15

850

7

15

The appliance, when installed, must be electrically

grounded in accordance with the requirements of the

authority having jurisdiction or in the absence of such

requirements, with the latest edition of the National

Electrical Code ANSI/NFPA No. 70. When the unit is

installed in Canada, it must conform to the Canadian

Electrical Code, C22.1, Part 1 and/or local Electrical Codes.

All wiring between the appliance and field installed devices

shall be made with wire having minimum 220ºF (105ºC)

rating. Line voltage wire external to the appliance must be

enclosed in approved conduit or approved metal clad cable.

To avoid serious damage,

DO NOT ENERGIZE

the

appliance until the system is full of water. Ensure that all air

is removed from the pump housing and piping before

beginning initial operation. Provide the appliance with

proper overload protection.

WARNING

This product must be properly grounded before any

electric current is applied to the blower or controls.

BLOWER MOTOR

The Valiant FT uses a 120V/1PH electrical supply to power

the blower motor. On ignition, after safety checks are

complete, the blower is provided with a signal to operate at

soft start level for burner ignition. After main burner ignition

is established, the motor receives a modulating signal from

the control corresponding to the rate of modulation

necessary.

AIR

PRESSURE

SWITCH,

BLOCKED

FLUE

&

CONDENSATE SWITCH

The air proving switch and blocked venting switch are wired

in series. When the error on the control shows “Air Switch

Open”, it could be a result of these switches. A minimum

pressure across the differential air switch proves the

combustion air fan. A failure of this switch to close could be

due to several factors such as, sensing line broken or loose

fitting, blocked vent, steady high wind condition or an

incorrectly set switch.

The Blocked Flue & Condensate switch is mainly due to a

blocked air intake or vent condition. When the blocked flue

switch has tripped, check the venting and/or air intake

piping for obstructions before placing the unit into operation.

Power must be shut off to the boiler and gas supply to the

appliance must be closed before attempting to investigate

reason for blocked flue condition.

PART 3 COMBUSTION COMPONENTS

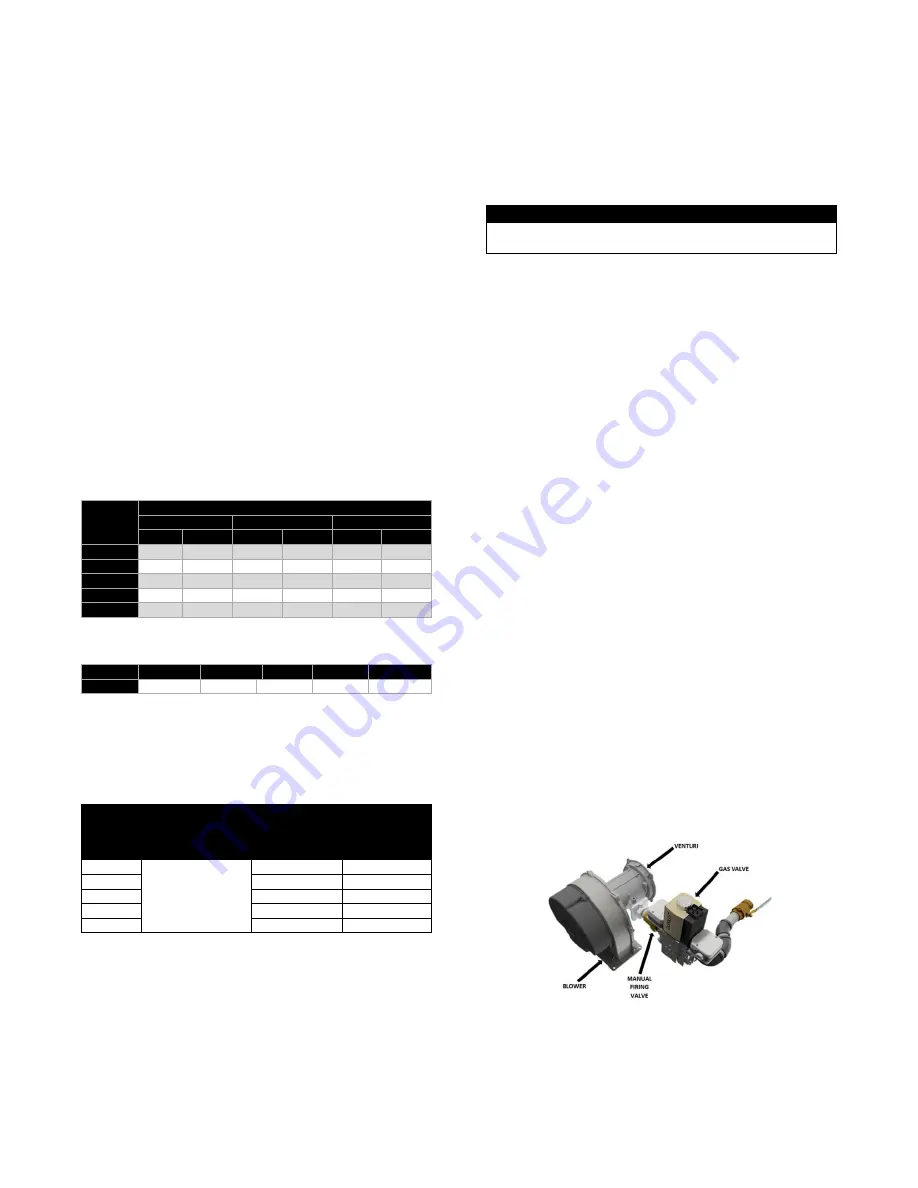

Figure 19: Combustion Components Assembly

(VA600-850 gas train displayed)

3.1

AIR/ GAS RATIO CONTROL VALVE

Operation of the gas valve in combination with the

combustion air fan allows the burner input rate to vary from

Summary of Contents for Valiant-FT II Series

Page 2: ...99 0419 Rev 00...

Page 40: ...36 PART 9 PIPING DIAGRAMS Figure 40 Single Boiler Hydronic Heating Zoned Piping...

Page 41: ...37 Figure 41 Multiple Boiler Hydronic Heating Zoned Piping...

Page 42: ...38 Figure 42 Single Boiler with DHW Tank Hydronic Heating Zoned Piping...

Page 43: ...39 PART 10 PARTS LIST...

Page 44: ...40...

Page 45: ...41...

Page 46: ...42...

Page 47: ...43...

Page 48: ...44...

Page 49: ...45...

Page 50: ...46...

Page 51: ...47...

Page 52: ...48...

Page 53: ...49...

Page 54: ...50...

Page 60: ...56 PART 11 TUBING DIAGRAM...

Page 61: ...57 PART 12 WIRING DIAGRAM...

Page 62: ...58...

Page 63: ...59...