5

2.4

LOCATION

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. This furnace shall be installed in

such a manner as to protect the electrical components

from water. Outdoor installation will lead to hazardous

electrical conditions and to premature furnace failure.

CAUTION

If this furnace is installed in an attic, it is important to

keep insulation at least 0.3 m (12") away from any

furnace openings. Some types of insulating material

may be combustible.

The unit must be installed in a location where the ambient

and return air temperature is over 15°C (60°F).

This furnace is approved for reduced clearances to

combustible construction. Therefore, it may be installed in a

closet or similar enclosure. As this unit may be installed as

an upflow, counter flow, or horizontal furnace, it may be

located in a basement, on the same level as the area to be

heated, suspended, or in a crawlspace. In any case, the unit

should always be installed level.

In a basement, or when installed on the floor (as in a

crawlspace), it is recommended that the unit be installed on

a concrete pad that is 2.5 cm to 5.0 cm (1" to 2") thick.

When installed in the counter flow position, this furnace

must not be installed on combustible flooring, unless the

approved sub-base is used (Model # KLASB0601DET).

Since the flue pipe is in counter flow position, be sure that

the clearances from the flue pipe to combustible

construction are maintained. Also, it is recommended to use

the

flue

pipe

protection

kit

KLADC0101DET

or

KLADC0201DET. Please refer to the Figure 1 and the

installation instructions included with the kit.

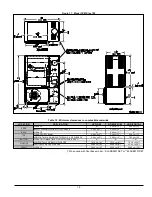

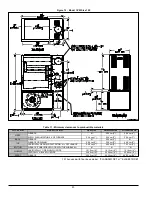

Figure 1 : Counterflow position, flue pipe protection

When installed in an horizontal position, the furnace may be

suspended by using an angle iron frame, as long as the total

weight of both the furnace and the frame are included in the

calculations. Other methods of suspension are acceptable.

When installed in the horizontal position, this furnace must

not be installed on combustible flooring, unless the

approved sub-base is used (Model KLASB0701DET).

The required minimum clearances for this furnace in all

positions are specified in Tables 7 and 8.

The furnace should be located as closely as possible to the

chimney or vent in order to keep vent connections short and

direct. The furnace should also be located near the centre of

the air distribution system.

2.4.1

Air for combustion and ventilation

This furnace should be installed in a location in which the

facilities for ventilation permit satisfactory combustion of oil,

proper

venting

and

the

maintenance

of

ambient

temperatures at safe limits under normal conditions of use.

The location should not interfere with the proper circulation

of air within the confined space. Refer to the CAN/CSA-

B139 installation code for complete regulations, and for

guidance on retrofit applications.

When this furnace is installed in a closet or similar

enclosure, 2 ventilation openings are required for

combustion air. The openings should be located about 15.2

cm (6") from the top and the bottom of the enclosure at the

front of the furnace. Table 1 indicates the minimum

dimensions required for each of these two ventilation

openings.

Table 1 : Minimum dimensions required in ventilation

openings

Input

(BTU/h)

Width

Height

75,000 – 105,000

45.72 cm (18")

20.32 cm (8")

120,000 – 155,000

50.80 cm (20")

25.40 cm (10")

WARNING

Do not block the combustion air openings in the

furnace.

Any

blockage

will

result

in

improper

combustion and may result in a fire hazard and/or cause

bodily harm.

The barometric draft regulator included with the furnace,

shall be installed in the same room or enclosure as the

furnace, in such a manner as to prevent any difference in

pressure between the regulator and the combustion air

supply.

Air requirements for the operation of exhaust fans, kitchen

ventilation systems, clothes dryers, and fireplaces shall be

considered in determining the adequacy of the space to

provide combustion air requirements.

In unconfined spaces, in buildings of conventional frame,

brick or stone construction, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue

gases. This determination must be made on an individual

installation basis and must take into consideration the

overall volume of the unconfined space, the number of

windows and ventilation openings, the number of doors to

DNS-0278 Rev. A

KLADC0101DET/

KLADC0201DET

Summary of Contents for CBMAAA060120

Page 21: ...21 Figure 13 Wiring diagram CVM ...

Page 22: ...22 Figure 14 Parts list CVMAAR036105 B50003 Rev D ...

Page 24: ...24 Figure 15 Parts list CVMAAR060120 B50004 Rev F ...

Page 48: ...23 Figure 13 Diagramme électrique CVM ...

Page 49: ...24 Figure 14 Liste de pièces CVMAAR036105 B50003 Rev D ...

Page 51: ...26 Figure 15 Liste de pièces CVMAAR060120 B50004 Rev F ...