10

A separate line voltage supply should be used with fused

disconnect switch or circuit breaker between the main power

panel and the unit.

Use only copper wire for 115V supply service to the unit.

Metallic conduit (where required/used) may terminate at the

side panel of the unit. It is not necessary to extend the

conduit inside the unit from the side panel to the control box.

When replacing any original furnace wiring, use only 105

o

C,

16 AWG copper wire.

2.4.3

24V Wiring

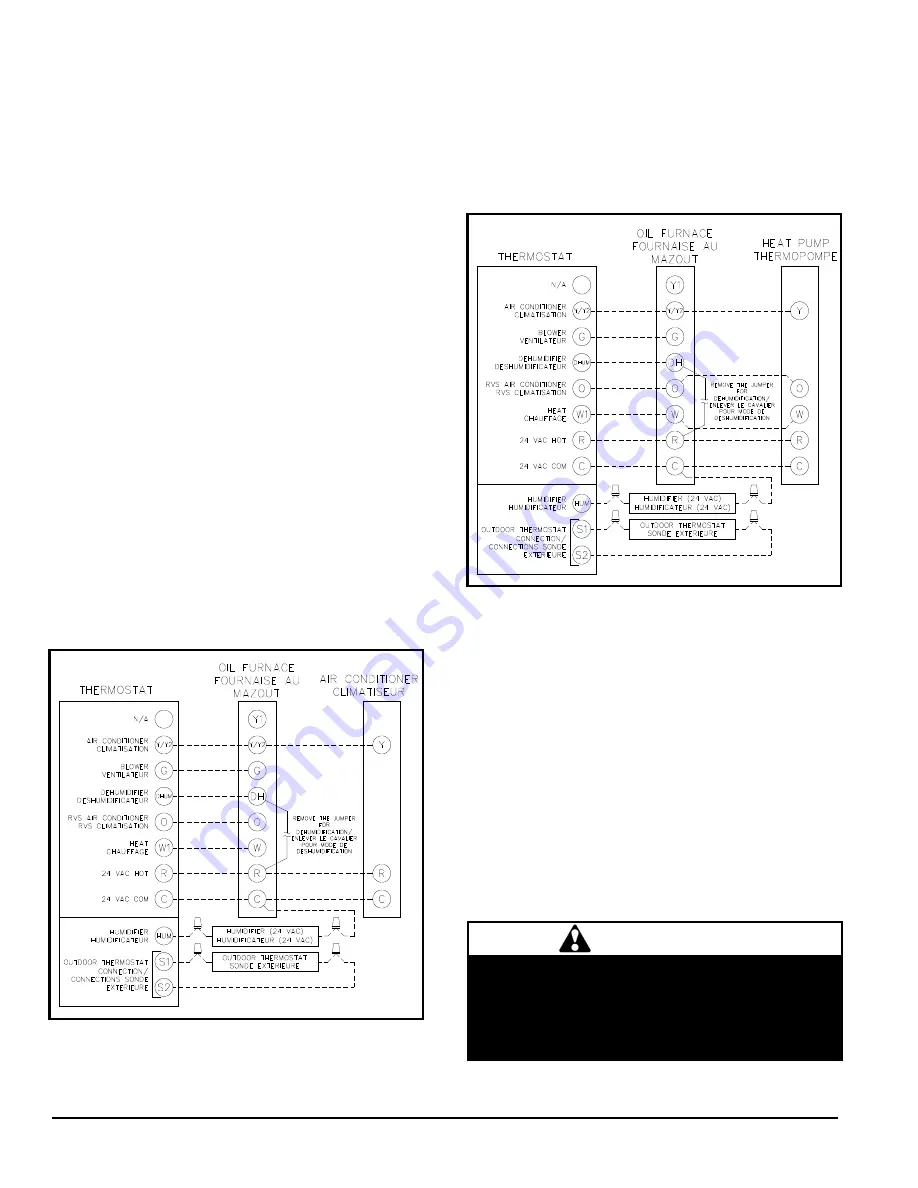

Instructions for wiring thermostat (field supplied) are packed

in the thermostat box. Make thermostat connections as

shown in Figures 9 and 10. Thermostat wire connections at

R and W are the minimum required for oil heating operation.

2.4.4

Accessory installation

General

When installing optional accessories on this appliance,

follow manufacturer’s Installation Instructions included with

accessory.

Auxiliary terminals

The HUM 120 VAC terminals on the electronic control board

are tied directly to the #8 pin of the 9-pin connector and

provide a 120 VAC signal whenever the burner is energized,

see Figure 13. The 120 VAC and neutral terminals can be

used for accessory wiring. See Electronic Air Cleaner and

Humidifier sections for further information.

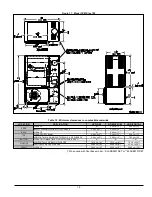

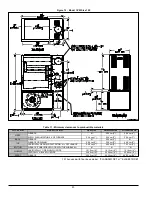

Figure 9 : 24 VAC Oil Furnace Wiring with Air

Conditioner

Electronic Air Cleaner

When adding an electronic air cleaner to this unit, use an

Airflow Sensor kit. As the air cleaner is connected to

constant 120 VAC power, the airflow sensor turns on the

electronic air cleaner when the furnace blower is operating.

Humidifier / Humidistat

A 24 VAC signal can be connected, sourced from the W and

C terminals on the electronic control board or a 120 VAC

signal from the HUM 120 VAC or N terminals, when a heat

source must be used.

Figure 10 : 24 VAC Oil Furnace Wiring with Heat Pump

Dehumidification capability with standard Humidistat

Dehumidification on systems using a variable speed motor

is better than on most other systems. If this feature is

required, the terminals on the electronic control board permit

the wiring of a standard humidistat. Refer to Figures 9 and

10 for wiring instructions.

A furnace equipped with a variable speed motor will detect

the opening of the humidistat contact and reduce the airflow

to 85% of nominal cooling airflow. This will increase its

capacity to dehumidify up to the point where the humidistat

detects an acceptable level of humidity in the air. At that

point the unit return to 100% of its cooling airflow.

To activate this mode, remove the jumper between DH

and R of the electronic board and wire in a standard

humidistat on these terminals.

2.4.8

Air filter

DANGER

Do not use this furnace as a construction heater. Use of

this furnace as a construction heater exposes it to

abnormal conditions, contaminated combustion air and

the lack of air filters. Failure to follow this warning can

lead to premature furnace failure and/or vent failure that

could result in a fire hazard and/or bodily harm.

An external filter rack is provided as standard equipment

with this furnace. The filter rack can be installed on the right

DNS-1024 Rev D

DNS-1025 Rev D

Summary of Contents for CBMAAA060120

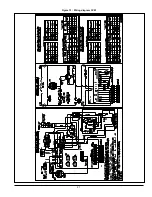

Page 21: ...21 Figure 13 Wiring diagram CVM ...

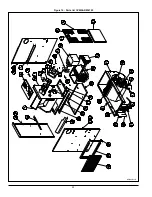

Page 22: ...22 Figure 14 Parts list CVMAAR036105 B50003 Rev D ...

Page 24: ...24 Figure 15 Parts list CVMAAR060120 B50004 Rev F ...

Page 48: ...23 Figure 13 Diagramme électrique CVM ...

Page 49: ...24 Figure 14 Liste de pièces CVMAAR036105 B50003 Rev D ...

Page 51: ...26 Figure 15 Liste de pièces CVMAAR060120 B50004 Rev F ...