8

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

•

Feed fan,

smooth regulation

(0% to 100 %)

.

•

Telescopic pull-out system of burner

Pell for easy maintenance

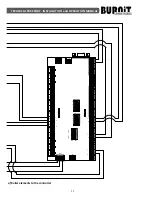

2.3. Safety devices of pellet boiler-and-

burner

A complex of safety devices provide for

the safety of the appliance. Air-feed fan,

step –regulated, controls the combustion

according to energy needs and is

maintained in optimal working order.

Independent STB thermostat shut-off the

burner and shut off the fuel feeding in

the combustion chamber in case of rising

boiler temperature.

•

Elbow-shape feeder chute.

The

geometrical shape of burner feeder

chute prevents backfire entry from

burner into pellet hopper. The flexible

tube is melted at a temperature above

80°C. Thus prevent access to the hopper

of the fire.

•

Thermostatic protection (80°С)

. The

thermostatic protection is fitted on the

feeder chute. When the surface of the

feeder chute reaches 80°С, the control

stops the feeding of pellets into the

burner and signals for fault (BB Alarm).

•

Fuse

. In case of electrical fault in the

system of the burner (short circuit,

current overload, etc.), the overload is

borne by the electrical fuse fitted on the

main control panel of the burner (10 А).

•

Power

interruption.

Innovative

controller

.

In case of power interruption,

all parameter settings are stored in the

memory of the controller. Upon the

subsequent restart of the burner, the

controller resumes the execution of

the program from the point when the

power interruption occurred.

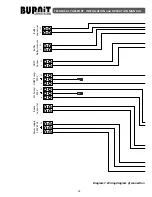

2.4. Design of pellet auger

The auger transports pellets from fuel

hopper to burner. Auger elements are:

auger pipe, auger hose, motor, conveyor

belt for moving the pellets.

Diagram 3. Design of pellet auger

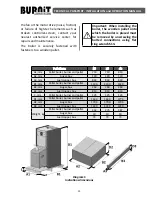

2.5. Design of fuel hopper FH 500-V2

Pellet hopper, designated to serve

biomass pellet-fired boilers. Pellet hopper

design allowing installation by choice

on either side of boiler. Made of cold-

rolled steel sheets with PVC coating.

Comfortable pellet charging hatch . Pellets

inside hopper are fed into auger in order

of reception. Precision leveling of hopper

possible via screw-in legs. Inspection side

openings for easy emptying and cleaning

of fuel hopper.

The hopper capacity is determined using

as calculation base the daily or weekly

fuel consumption rate of burner. The

pellet hopper usable volume of 500 litters

allows charging of 280-300 kg of pellets

with diameter 6-8 mm, and top-up/refill

once a week (for burner of rated power

up to 40 kW).