26

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

8. FILLING THE HEATING INSTALLATION

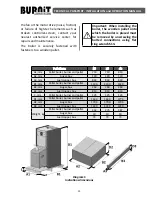

Table 6

Problem

Prevention

Possible installation damage due

to strains in the material caused

by temperature differences

Fill the heating installation only in cold conditions

(inlet temperature must not exceed 40°C).

Danger of installation damage

due to accumulation of deposits

Condensate formation and tar

deposits may shorten boiler’s

operational life.

- Do not operate the heating boiler for a long period

of time in partial load mode

- The temperature at the boiler inlet must not be

less than 65°C, boiler water temperature must be

between 80°C and 85°C.

- Use the boiler for a short period to heat warm

water in the summer.

9. OPERATION OF BOILER

Failure to observe the installation

and operating requirements

described in the manual and

the service booklet voids the

warranty.

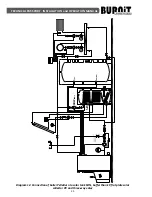

9.1.

Operation of pellet boiler

PelleBurn with pellet burner Pell

Ignition.

After starting the burner up from

the control panel, the main pellet auger

conveys certain amount of fuel from the

pellet hopper to the burner. This specific

amount of pellets is set by the installer

and depends on the fuel characteristics.

The fed-in quantity of pellets is conveyed

from the auger conveyor built in the

burner to the combustion chamber where

it is being ignited using hot air.

Burning.

The burning process takes

place in the combustion chamber and,

after it has been fed into the combustion

chamber, the fuel is then transported

from the internal auger conveyor to the

combustion chamber in portions. This

allows for constant and optimal burning

rate of the fuel. The boiler is controlled and

operated by sensor exhaust. This sensor

measures the temperature of exhaust

gases and provides information to the

control unit ignition or discontinuation

of combustion. The output of the burner

is determined by the intervals preset on

the control panel taking into account the

heating value, size and density of the

pellets.

Automatic cleaning system

. The pellet

boiler is equipped with innovative

automatic cleaning system for combustion

chambers of both devices.

A powerful cleaning motor built in the

burner body, air is being blown in at high

speed and rate thus removing all residues

– ash, noncombustible inclusions, etc.

built up into the combustion chamber of

the boiler.

At the same time the boiler turns

on automatic ash removal which is

transported to the ash container through

screw located in the lower part. These

automatic cleaning cycles last several

seconds and can be additionally adjusted

as well as their repeat rate depending on

the load of the burner.