25

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn

on any exhaust fans, such as range-hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

4. Place in operation the appliance being inspected.

Follow the Lighting (or Operating) Instructions.

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

condition of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the

National Fuel Gas Code

, NFPA

54/ANSI Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the minimum

size as determined using the appropriate tables in

Part 11 in the

National Fuel Gas Code

, NFPA 54/

ANSI Z223.1.

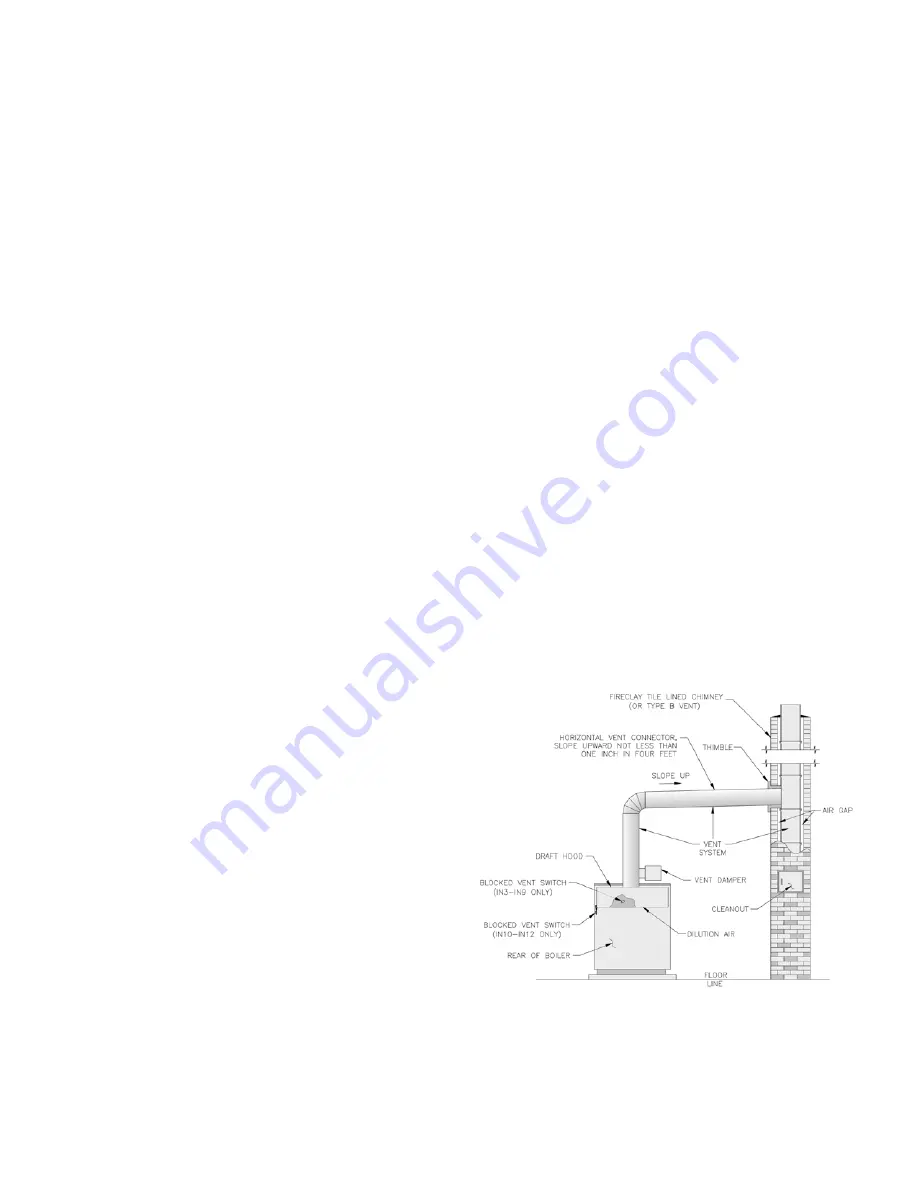

D.

Install Vent Connector

from draft hood or vent

damper to chimney. See Figure 30.

1. Do not connect into same leg of chimney serving an

open fireplace.

2. Vent pipe to chimney must not be smaller than outlet

on draft hood or vent damper. Type B is

recommended, but single-wall vent pipe may be

used. Arrange venting system so boiler is served by

vent damper device.

3. Where two or more appliances vent into a common

vent, the area of the common vent should be at least

equal to the area of the largest vent plus 50% of the

area in the additional vent(s). Do not connect the

vent of this appliance into any portion of mechanical

draft systems operating under positive pressure.

4. Horizontal run should be as short as possible. The

maximum length of an uninsulated horizontal run

must not exceed 75% of the height of the chimney.

5. Vent pipe should have the greatest possible initial

rise above draft hood consistent with headroom

available and required clearance from adjacent

combustible building structure. Vent pipe should be

installed above bottom of chimney to prevent

blockage.

6. Vent pipe should slope upward from draft hood to

chimney not less than one inch in four feet. No

portion of vent pipe should run downward or have

dips or sags. Vent pipe must be securely supported.

7. Vent pipe must be inserted into but not beyond

inside wall of chimney liner. Seal tight between vent

pipe and chimney.

E.

If an Existing Boiler is Removed:

When an existing boiler is removed from a common

venting system, the common venting system is likely to

be too large for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system are

not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion, and other

deficiencies which could cause an unsafe condition.

Figure 30: Typical Vent Installation

Summary of Contents for INDEPENDENCE IN10 CANADA

Page 4: ... Figure 1 Dimensional Drawing ...

Page 18: ...18 Figure 25 Recommended Water Piping for Circulator Zoned Heating System ...

Page 19: ...19 Figure 25A Recommended Water Piping for Zone Valve Zoned Heating System ...

Page 28: ...28 Figure 34 Vent Damper Schematic Wiring Diagram Figure 33 Vent Damper Harness to Limit ...

Page 29: ...29 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 30: ...30 Figure 35 Wiring Diagrams Steam Continuous Ignition Standing Pilot Probe Low Water Cutoff ...

Page 32: ...32 Figure 36 Wiring Diagrams Steam Intermittent Ignition EI Probe Low Water Cutoff ...

Page 34: ...34 Figure 37 Wiring Diagrams Steam Continuous Ignition Standing Pilot Float Low Water Cutoff ...

Page 36: ...36 Figure 38 Wiring Diagrams Steam Intermittent Ignition EI Float Low Water Cutoff ...

Page 40: ...40 Figure 40 Wiring Diagrams Water Intermittent Ignition EI Intermittent Circulation ...

Page 42: ...42 Figure 41 Wiring Diagrams Water Continuous Ignition Standing Pilot Gravity Circulation ...

Page 44: ...44 Figure 42 Wiring Diagrams Water Intermittent Ignition EI Gravity Circulation ...

Page 46: ...46 Figure 43 Wiring Diagrams Water Continuous Ignition Standing Pilot Tankless Heater ...

Page 48: ...48 Figure 44 Wiring Diagrams Water Intermittent Ignition EI Tankless Heater ...

Page 51: ...51 Figure 48 Lighting Instructions Continuous Ignition System VR8200 and VR8300 Gas Valves ...

Page 52: ...52 Figure 49 Lighting Instructions Continuous Ignition System 7000 ERHC Gas Valve ...

Page 66: ...66 Honeywell Electronic Ignition Trouble Shooting Guide ...

Page 67: ...67 Honeywell Hot Surface to Pilot Trouble Shooting Guide ...

Page 80: ...80 ...

Page 84: ...84 ...

Page 87: ...87 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 88: ...88 ...