4-58

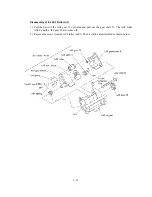

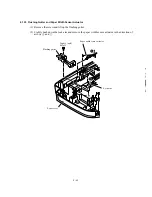

4.1.23 Encoder Strip and Carriage Motor

(1) At the left end of the encoder strip, unhook the spring from the main chassis.

NOTE:

Take care not to scratch or damage the encoder strip.

150

C16

This should point up.

Encoder strip

Encoder strip

spring

"c"

Idle pulley holder

"b"

"a"

Pulley

spring

Strip guide

Carriage

Encoder strip

Main chassis

Main chassis

Carriage motor pulley

"a": Screw, pan (s/p washer) M3x8

"b": Shoulder screw

"c": Taptite, cup S M3x6

(2) Move the carriage to the center of its travel.

(3) Loosen two screws "a" and "c" on the idle pulley holder. (See the above illustration.)

(4) While pushing the idle pulley holder to the right, remove the timing belt from the carriage

motor pulley and idle pulley.

Summary of Contents for MFC-5100C

Page 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC5100C MFC590 ...

Page 4: ...CHAPTER 1 GENERAL DESCRIPTION ...

Page 11: ...CHAPTER 2 INSTALLATION ...

Page 19: ...CHAPTER 3 THEORY OF OPERATION ...

Page 39: ...CHAPTER 4 DISASSEMBLY REASSEMBLY LUBRICATION AND ADJUSTMENT ...

Page 114: ...4 73 7 Paper ejection roller gear and PF roller gear 8 Paper feed roller and PF spring ...

Page 116: ...4 75 11 Purge shaft ...

Page 119: ...4 78 Head Positioning Test Pattern ...

Page 120: ...CHAPTER 5 MAINTENANCE MODE ...

Page 127: ...5 6 Scanning Compensation Data List ...

Page 141: ...5 20 Vertical Alignment Check Pattern ...

Page 148: ...CHAPTER 6 ERROR INDICATION AND TROUBLESHOOTING ...

Page 173: ...MFC5100C MFC590 Appendix 1 EEPROM Customizing Codes ...

Page 176: ...MFC5100C MFC590 Appendix 2 Firmware Switches WSW ...

Page 220: ...A Main PCB 1 6 ...

Page 221: ...A Main PCB 2 6 ...

Page 222: ...A Main PCB 3 6 ...

Page 223: ...A Main PCB 4 6 ...

Page 224: ...A Main PCB 5 6 ...

Page 225: ...A Main PCB 6 6 ...

Page 226: ...R27 100 R28 100 R29 100 R30 100 B Relay PCB ...

Page 227: ...C NCU PCB ...

Page 228: ...D Control Panel PCB 1 2 ...

Page 229: ...D Control Panel PCB 2 2 ...

Page 230: ...E Power Supply PCB ...