HL-2030/2040/2070N SERVICE MANUAL

Confidential

7-17

5. SOFTWARE SETTING PROBLEMS

The printer may not print the data correctly if there are incorrect software settings.

S-1

“There was an error writing to LPT1: (or BRUSB) for the printer” error message

appears.

User Check

(1) Check that the printer cable is not damaged or broken. Check also that the cable is connected

to the correct interface connectors of both the printer and PC.

(2) Check that the correct printer is selected if you have an interface switching device.

(3) Check that the appropriate printer driver is selected as ‘Set as Default’. Check also that the

correct print port is set for the selected printer driver.

(4) Check that the printer is not connected to the same port which is also connected to a mass

storage device or scanner. Remove all other devices and connect the port to the printer only.

Turn off the printer status monitor in the device options tab in the printer driver.

(5) If the print port is set as an ECP port, change it to a normal port.

(6) Try printing the test page refer to

‘Test Sample Page’ in Chapter 8.

(7) Try resetting the factory settings.

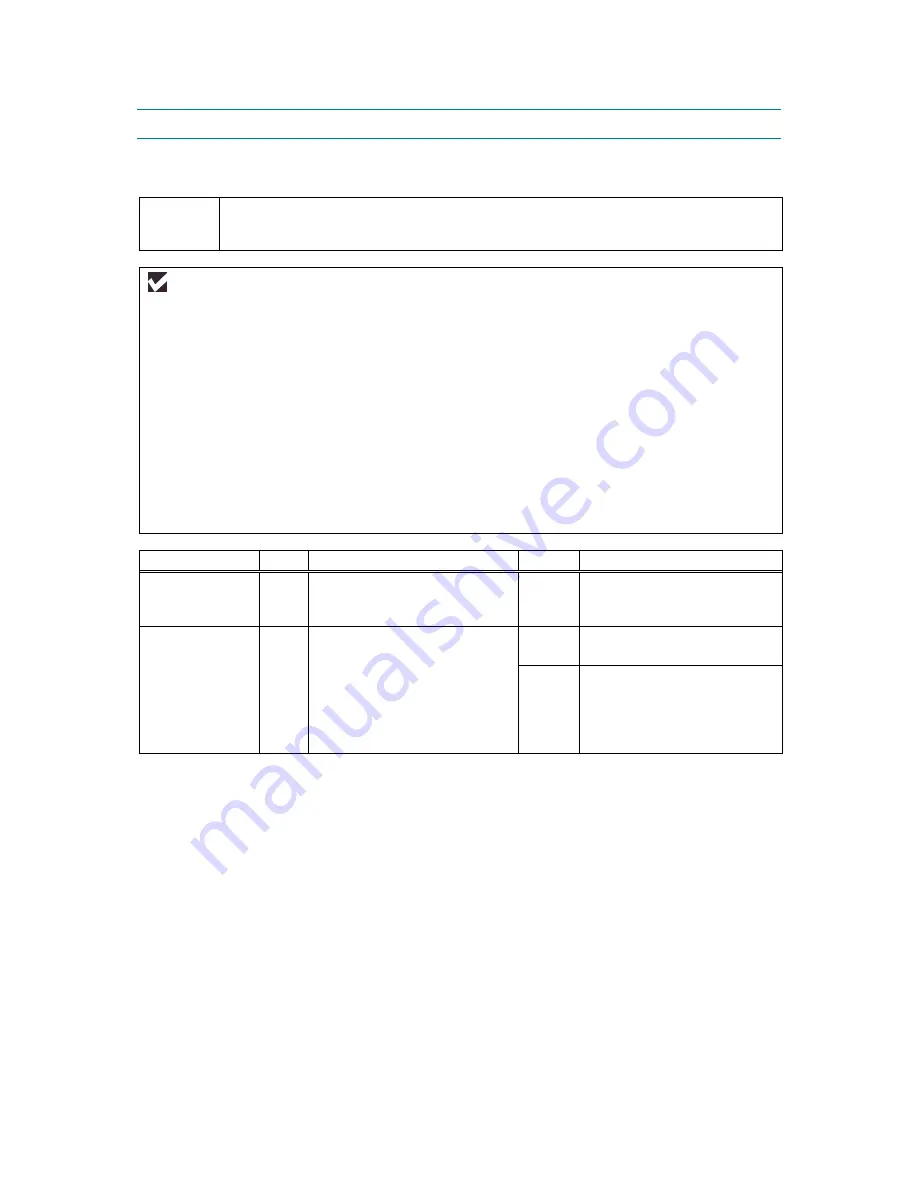

Possible cause

Step

Check

Result

Remedy

Failure inside

the printer

1

Is it possible to print the test

page with the method of

‘Test

Sample Page’ in Chapter 8.?

No

Identify the error type, then

refer to the specified section

of this chapter.

Main PCB

failure

2

Is it possible to print with

another PC and printer cable?

No

Replace the main PCB.

Yes

This problem may appear

under the specified system

environment. Check the

environment which the user

used.