With the above-specified settings, the effective commutation offset

(P-0-0521) is automatically calculated on switching to operating mode. The

drive is ready for power activation.

The procedure “Reference point optimum commutation offset”

cannot be used in the case of analog Hall units, as the necessary

parameter P-0-0508 already uses the procedure “Commutation

via analog Hall units”.

Commutation by means of digital

Hall unit

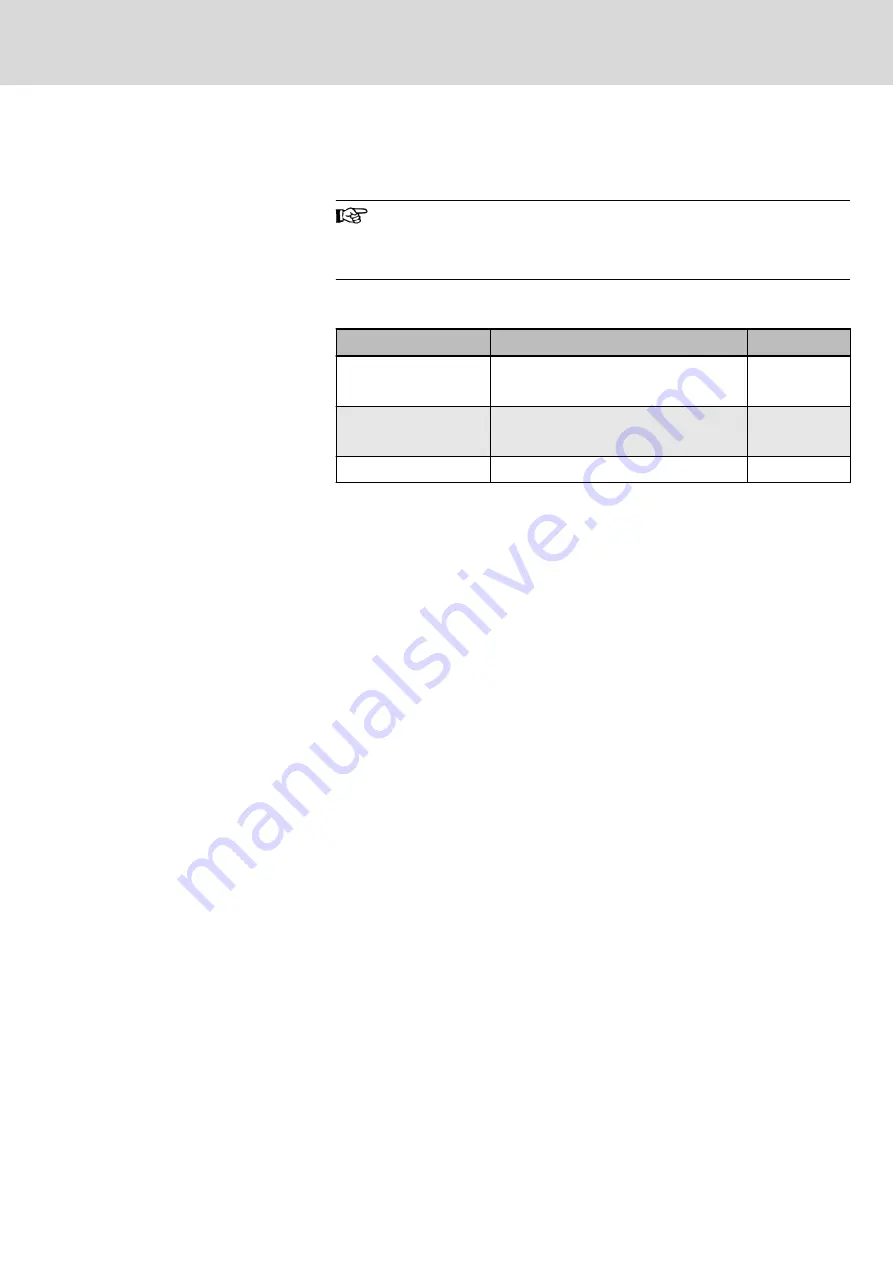

For operation on Rexroth IndraDrive Cs, the following sercos parameters

must be edited before commissioning:

Ident number

Description

Value

P-0-0509

(for MCP020)

Rough commutation offset

1)

946

P-0-0509

(for MCP030 ... 070)

Rough commutation offset

1)

62

P-0-0074

Encoder type 1 (motor encoder)

23

1)

The parameter is used to enter the motor depending constants.

It is not the actually commutation offset. This is displayed with‐

in parameter P-0-0521 “Effective commutation offset” after au‐

tomatic calculation.

Tab. 14-5:

Parameters to be checked before commutation adjustment

With the above-specified settings, the effective commutation offset

(P-0-0521) is automatically calculated on switching to operating mode. Com‐

mutation by means of digital Hall unit only enables reaching of an electrical

accuracy of +/- 30°. In this respect, a maximum power loss of 14 % is to be

expected.

Hence the maximum motor force is available, a “Reference point optimum

commutation offset” must be stored on the reference point.

Procedure at IndraDrive Cs:

1.

Activate initial commissioning mode (P-0-0522, bit 15)

2.

Carry out commutation adjustment using the sinusoidal procedure.

3.

Switch axis to "AF".

4.

Start fine commutation.

5.

Initiate reference point run.

If the reference point is reached, the "reference point of optimum com‐

mutation offset" (P-0-0508) is placed there.

6.

Deactivate initial commissioning mode.

On each restart of the machine, the rough commutation offset (+/- 30°) is de‐

termined by switching to operating mode. The drive may now run to the refer‐

ence point with reduced force. If the reference point is reached or passed, the

optimum reference point for the commutation offset is applied by the drive

and the maximum force is available to the axis.

14.6.4

Measuring procedure: Measuring of the relation between primary and

secondary part

For commutation setting, this procedure requires determination of the relative

position of the primary part in relation to the secondary part. This procedure

has the advantage that commutation adjustment does not require any power

MCL Ironless Linear Motors

177/197

Commissioning, operation and maintenance

R911330592_Edition 06 Bosch Rexroth AG

Summary of Contents for rexroth MCL

Page 1: ...MCL Ironless Linear Motors Project Planning Manual R911330592 Edition 06 ...

Page 16: ...8 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 52: ...44 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 57: ...MCL Ironless Linear Motors 49 197 Dimension sheets R911330592_Edition 06 Bosch Rexroth AG ...

Page 68: ...60 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 90: ...82 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 104: ...96 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 162: ...154 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 174: ...166 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 196: ...188 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 198: ...190 197 MCL Ironless Linear Motors Bosch Rexroth AG R911330592_Edition 06 ...

Page 204: ...Notes 196 197 MCL Ironless Linear Motors ...