10

Climate 5000 MS – 6720887246 (2018/04)

Refrigerant Piping Connection

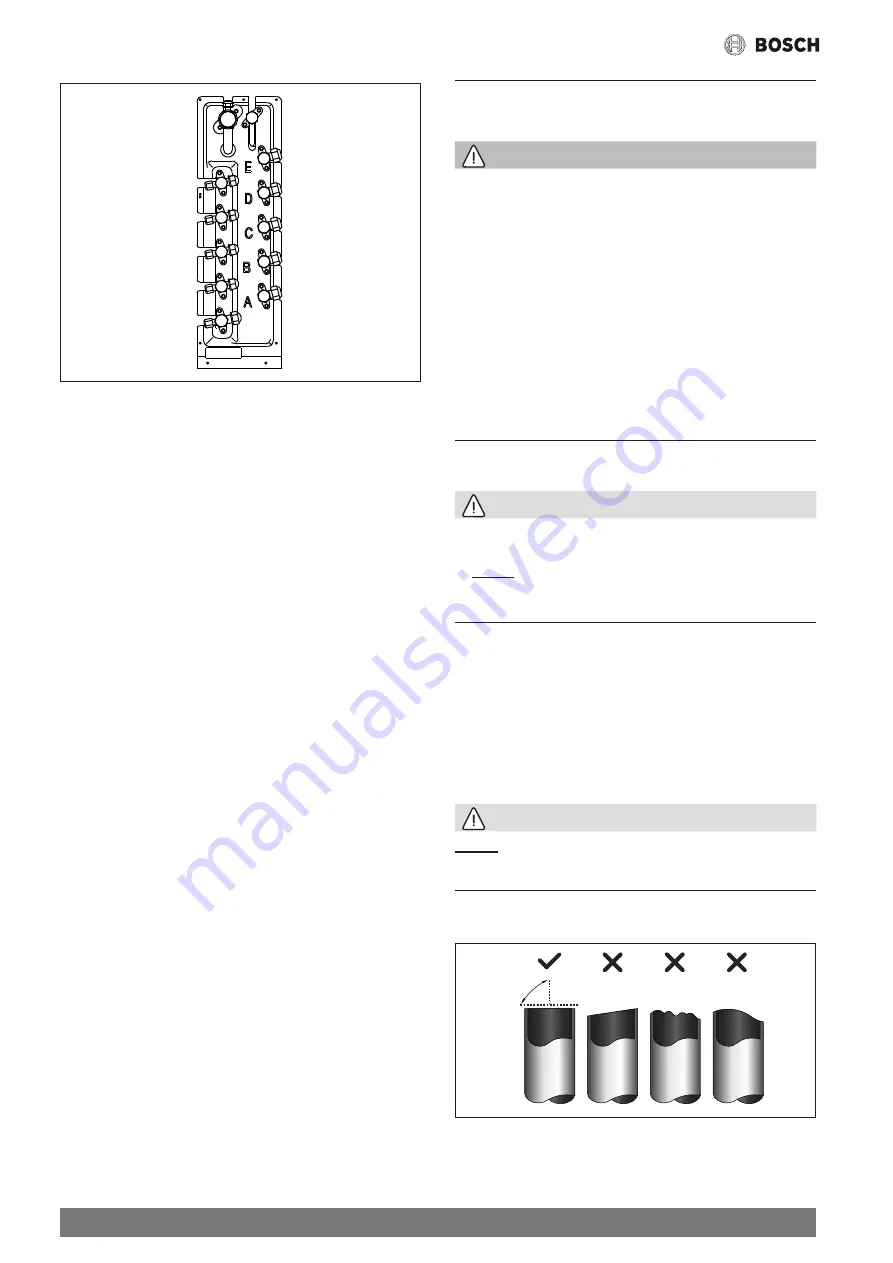

Fig. 13.

7

Refrigerant Piping Connection

Safety Precautions

WARNING

•

All installation piping must be completed by Qualified Personnel

and must comply with the local and national regulations.

•

When the air conditioner is installed in a small room, measures must

be taken to prevent the refrigerant concentration in the room from

exceeding the safety limit in the event of refrigerant leakage. If the

refrigerant leaks and its concentration exceeds its proper limit,

hazards due to lack of oxygen may result.

•

When installing the refrigeration system, ensure that air, dust,

moisture or foreign substances do not enter the refrigerant circuit.

Contamination in the system may cause poor operating capacity,

high pressure in the refrigeration cycle, explosion or injury.

•

Ventilate the area immediately if there is refrigerant leakage during

the installation. Leaked refrigerant gas is both toxic and flammable.

Ensure there is no refrigerant leakage after completing the installa-

tion work.

Refrigerant Piping Connection Instructions

CAUTION

•

The branching pipe must be installed horizontally. An angle of more

than 10° may cause malfunction.

•

DO NOT

install the connecting pipe until both indoor and outdoor

units have been installed.

•

Insulate both the gas and liquid piping to prevent water leakage.

Step 1: Cut pipes

When preparing refrigerant pipes, take extra care to cut and flare them

properly. This will ensure efficient operation and minimize the need for

future maintenance.

For R32 refrigerant models, the pipe connection

points must be placed outside of the room.

1. Measure the distance between the indoor and outdoor units.

2. Using a pipe cutter, cut the pipe a little longer than the measured

distance.

CAUTION

DO NOT

deform the pipe while cutting. Be extra careful not to damage,

dent, or deform the pipe while cutting. This will drastically reduce the

heating efficiency of the unit.

1. Ensure that the pipe is cut at a perfect 90° angle. Refer to Fig. 14 for

examples of bad cuts

90°

Oblique

Rough

Warped

Fig. 14.