- 17 -

USE

USEFUL ADVICE

advised to have the following checks car-

ried out:

condensing heat exchanger

•

burner;

•

exhaust fume duct and fl ue;

•

pressurisation of the expansion tank;

•

fi lling up of the central heating circuit;

•

bleeding of air from the central heating

•

system;

general check of the appliance’s opera-

•

tion.

External cleaning

3.5

Before carrying out any clean-

ing, disconnect the appliance

from the electrical mains, using

the fused spur isolation switch

fi tted adjacent to the appliance.

To clean the external panels, use a cloth

soaked in soapy water. Do not use solvents,

abrasive powders or sponges.

Do not

carry out cleaning of the appliance

and/or its parts with readily fl ammable sub-

stances (for example petrol, alcohols, naph-

tha, etc.).

Operational faults

3.6

If the boiler does not function and a code

that alternates between the letter

Er

and the

writing

reset

(

see "LCD general features" to

page 10

) appear on the LCD display, it indi-

cates that the safety lock-out has stopped

the boiler. The display background fl ashes

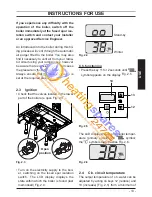

( Fig. 3.3 ).

Fig. 3.3

RESET

RESET

For the fi rst lighting up and following main-

tenance procedures for the gas supply, it

may be necessary to repeat the resetting

operation several times so as to remove the

air present in the pipe work.

Safety lock-out may occur even in case of a

blockage of the condensate drainage (e.g.

plugged drain pipe). It is advisable to check

the condensate drainage pipe and traps for

cleanness.

Press the reset key on the boiler control

panel 11 ( Fig. 3.1 ) to reset its functioning.

In this case and in case of per-

sistent lock-out call a competent

and responsible Service Engi-

neer.

Other operational faults signalled on the

LCD display

If the LCD display displays a code that al-

ternates between the letter

Er

and the

symbol, the boiler has an anomaly that can-

not be reset.

The display background fl ashes ( Fig. 3.4 ).