page 90

page 90

page 90

page 90

page 90

160B&C TM

800-00140

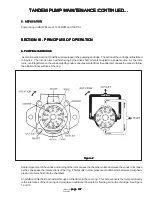

1. Direct Drive: A pilot on the pump mounting flange assures correct mounting and shaft alignment, provided

the pilot is firmly seated in the accessory pad of the power source. Care should be exercised in tightening

all flange mounting screws to prevent misalignment.

If gaskets are used between flanges, they should be installed carefully so as to lie flat and should not be the

type that will take a set. Shaft keys and couplings must be properly seated to avoid slipping and possible

shearing.

Proper coupling alignment is essential to prolong pump life.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Pump shafts are designed to be installed in couplings

Pump shafts are designed to be installed in couplings

Pump shafts are designed to be installed in couplings

Pump shafts are designed to be installed in couplings

Pump shafts are designed to be installed in couplings

with a slip fit or very light press. Pounding the coupling

with a slip fit or very light press. Pounding the coupling

with a slip fit or very light press. Pounding the coupling

with a slip fit or very light press. Pounding the coupling

with a slip fit or very light press. Pounding the coupling

on the shaft can ruin the bearings. Shaft tolerances

on the shaft can ruin the bearings. Shaft tolerances

on the shaft can ruin the bearings. Shaft tolerances

on the shaft can ruin the bearings. Shaft tolerances

on the shaft can ruin the bearings. Shaft tolerances

are shown on the pump installation drawings.

are shown on the pump installation drawings.

are shown on the pump installation drawings.

are shown on the pump installation drawings.

are shown on the pump installation drawings.

2. Indirect Drive: Indirect drive is not recommended for these pumps.

B. SHAFT ROTATION

B. SHAFT ROTATION

B. SHAFT ROTATION

B. SHAFT ROTATION

B. SHAFT ROTATION

NOTE:

NOTE:

NOTE:

NOTE:

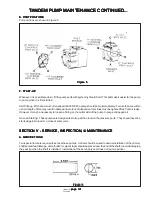

NOTE: Pumps are normally assembled for right hand (clockwise) rotation as viewed from the shaft end. A pump

made for left hand rotation is identified by an “L” in the model code.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: If it is desired to reverse the direction of drive rotation, it is necessary disassemble the pump and

reverse the location of the cartridge inlet and the outlet support plates. Use rotational arrows on

inlet plate for proper screwholes. (See Section VI)

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Never drive a pump in the wrong direction of rotation.

Never drive a pump in the wrong direction of rotation.

Never drive a pump in the wrong direction of rotation.

Never drive a pump in the wrong direction of rotation.

Never drive a pump in the wrong direction of rotation.

Scoring may result, necessitating extensive repairs.

Scoring may result, necessitating extensive repairs.

Scoring may result, necessitating extensive repairs.

Scoring may result, necessitating extensive repairs.

Scoring may result, necessitating extensive repairs.

C. PIPING AND TUBING

C. PIPING AND TUBING

C. PIPING AND TUBING

C. PIPING AND TUBING

C. PIPING AND TUBING

1. All pipes and tubing must be thoroughly cleaned before installation. Recommended methods of cleaning

are sandblasting, wirebrushing, and pickling.

2. To minimize flow resistance and the possibility of leakage, use only as many fittings and connections as

necessary for proper installation.

3. The number of bends in tubing should be kept to a minimum to prevent excessive turbulence and friction of

oil flow. Tubing must not be bent too sharply. The recommended radius for bends is three times the inside

diameter of the tube.

D. OVERLOAD PROTECTION

D. OVERLOAD PROTECTION

D. OVERLOAD PROTECTION

D. OVERLOAD PROTECTION

D. OVERLOAD PROTECTION

Relief valves must be installed in the system as close to the pump outlets as possible. The relief valves limit

pressure in each system to a prescribed maximum and protects components from excessive pressure. Each relief

valve pressure setting depends on the work requirements of the circuit being fed.

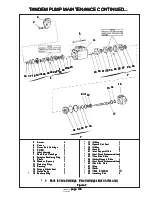

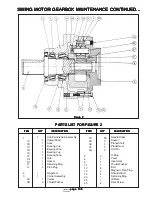

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...

TANDEM PUMP MAINTENANCE CONTINUED...