page 24

page 24

page 24

page 24

page 24

160B&C TM

800-00140

FUEL AND LUBRICANTS

FUEL AND LUBRICANTS

FUEL AND LUBRICANTS

FUEL AND LUBRICANTS

FUEL AND LUBRICANTS

FUEL SPECIFICATIONS

FUEL SPECIFICATIONS

FUEL SPECIFICATIONS

FUEL SPECIFICATIONS

FUEL SPECIFICATIONS

Use grade no. 2-D fuel above 40 degrees F.

Use grade no. 1-D fuel below 40 degrees F.

Use grade no. 1-D fuel for all air temperatures at altitudes.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Change the engine oil at one half the normal interval if fuel sulfur content exceeds 0.5%. Use

fuel with less than 1.0% sulfur. Use fuel with less than 0.5% sulfur if possible.

Sediment and water should not exceed 0.10% for maximum filter life.

The Cetane number should be 40 minimum. A fuel with a higher Cetane number may be required if operating the

machine where air temperatures are normally low or where altitudes are high. In cold weather operation, the

cloud point should be 10 degrees F. below lowest normal air temperatures.

FUEL STORAGE

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Diesel fuels stored for a long time may form gum or bacteria and plug filters.

Keep fuel in a clean container and store in a protected area. Water and sediment must be removed before fuel

gets to the engine. Do not use de-icers to remove water from fuel. Do not depend on fuel filters to remove

water.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Keep all dirt, scale, water, or other foreign material out of fuel.

Store fuel drums on sides with plug up.

ENGINE OIL

Refer to the Engine Service Book supplied loosely with the machine.

Refer to the Engine Service Book supplied loosely with the machine.

Refer to the Engine Service Book supplied loosely with the machine.

Refer to the Engine Service Book supplied loosely with the machine.

Refer to the Engine Service Book supplied loosely with the machine.

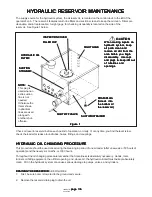

HYDRAULIC OIL

The following lists some features to look for in an oil. The hydraulic oil for the machine should feature:

-

Rust resistant additives to prevent rust formation from moisture condensation.

-

Anti-foaming agents to break up air bubbles and prevent "foaming" that may cause sluggish and

erratic operation.

-

High stability to resist oxidation and prevent varnish formation and deposits that foul systems.

-

Anti-wear properties to prevent scuffing and exccesive wear at high speeds and high pressures.

-

Good viscosity index for easy flow at low temperatures without thinning out at high temperatures

after hours of use.