page 84

page 84

page 84

page 84

page 84

160B&C TM

800-00140

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Before assembling the shaft seal, determine the correct position of the sealing lip. (See Figure 9).

Seals are assembled with the garter spring toward the pumping cartridge. Press the seal firmly in

place and lubricate the lip with petroleum jelly or other grease compatible with the system fluid. Slide

the drive shaft into the body until the bearing is seated. Tap lightly on the end of the shaft if

necessary. Install the snap ring.

Figure 9

Figure 9

Figure 9

Figure 9

Figure 9

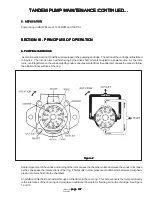

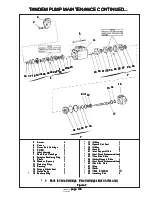

Install new o-rings in the body and cover. Insert the ring locating pins in the body and assemble the ring

so that the arrow on the perimeter points in the direction of rotation. Check the assembly against Figure

10. Install the rotor on the shaft and insert the vanes in the rotor slots. Be certain the radius edges of the

vanes are toward the cam ring.

Figure 10

Figure 10

Figure 10

Figure 10

Figure 10

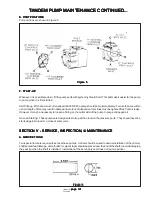

Place the pressure plate on the locating pins and flat against the ring. Place the spring over the pressure

plate, and then install the cover with the outlet port in the correct position. Tighten the cover screws to

the torque shown in Figure 8. Rotate the shaft by hand to insure that there is no internal binding. Install

the shaft key.

If a foot mounting is used, assemble the pump to it’s foot mounting. If a gasket is used, be certain it is

flat to avoid misalignment of the shaft.

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...

SERVO PUMP MAINTENANCE CONTINUED...