page 71

page 71

page 71

page 71

page 71

160B&C TM

800-00140

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: If the shaft bearings, shaft, valve block, or housing were not replaced, use the bearing spacer removed during the

disassembly procedure to preload the shaft bearings and perform step H. 13. If preload adjustment is

necessary, perform steps H.7. through H.13.

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

TA-19 SWING PUMP MAINTENANCE CONTINUED...

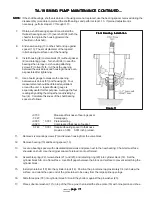

Front Bearing Installation

Front Bearing Installation

Front Bearing Installation

Front Bearing Installation

Front Bearing Installation

Figure 11

Figure 11

Figure 11

Figure 11

Figure 11

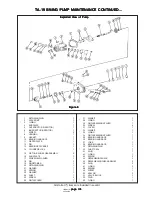

7.

Obtain a shaft bearing spacer kit and install the

thickest bearing spacer (13) over shaft (24) with the

chamfer facing into the housing (toward the

shoulder on the shaft).

8.

Slide new bearing (10) on the shaft and up against

spacer (13). The small diameter of the tapered

roller bearing must face out of the housing.

9.

Install housing (8) to valve block (51) without gasket

(9) and rotating group. Turn shaft (24) to seat the

bearings then torque to six housing attaching

screws (7) to five (5) lb. in. Check the opening

between the valve block and housing to be as even

as possible after tightening.

10.

Use a feeler gauge to measure the opening

between valve block (51) and housing (8). Four

measurements should be obtained equidistant

around the unit. A tapered feeler gauge is

especially useful for this purpose. Average the four

readings by adding them together and dividing by

four (4). Calculate thickness of the shaft bearing

spacer as follows:

+0.150

Measured thickness of bearing spacer

- 0.027

Average gap

+0.003

0.001

Preload setting

+0.020

Compressed thickness of gasket

0.146

0.001

Required bearing spacer to thickness

provide a 0.003 0.001 inch preload.

11.

Remove six mounting screws (7) and remove housing from the valve block.

12.

Remove bearing (10) and bearing spacer (13).

13.

Locate a bearing spacer with calculated dimensions and place next to the new bearing. Chamfer must face

shoulder on shaft. Use the original spacer if preload is not performed.

14.

Assemble spring (22), two washers (21) and (23), and retaining ring (20) into cylinder block (14). Set the

cylinder block S/A on a flat surface. Use Kraft paper between the block and surface to prevent scratching the

cylinder block.

15.

Install pin retainer (19) into the cylinder block (14). Position the pin retainer approximately 1/4 inch below the

surface, and orient the open end of the pin retainer to be away from the large spline openings.

16.

Slide three pins (18) into cylinder block S/A until they bottom against the pin washer (23).

17.

Place spherical washer (17) on top of the three pins; then install the shoe plate (16) with nine piston and shoe

+

-

+

-