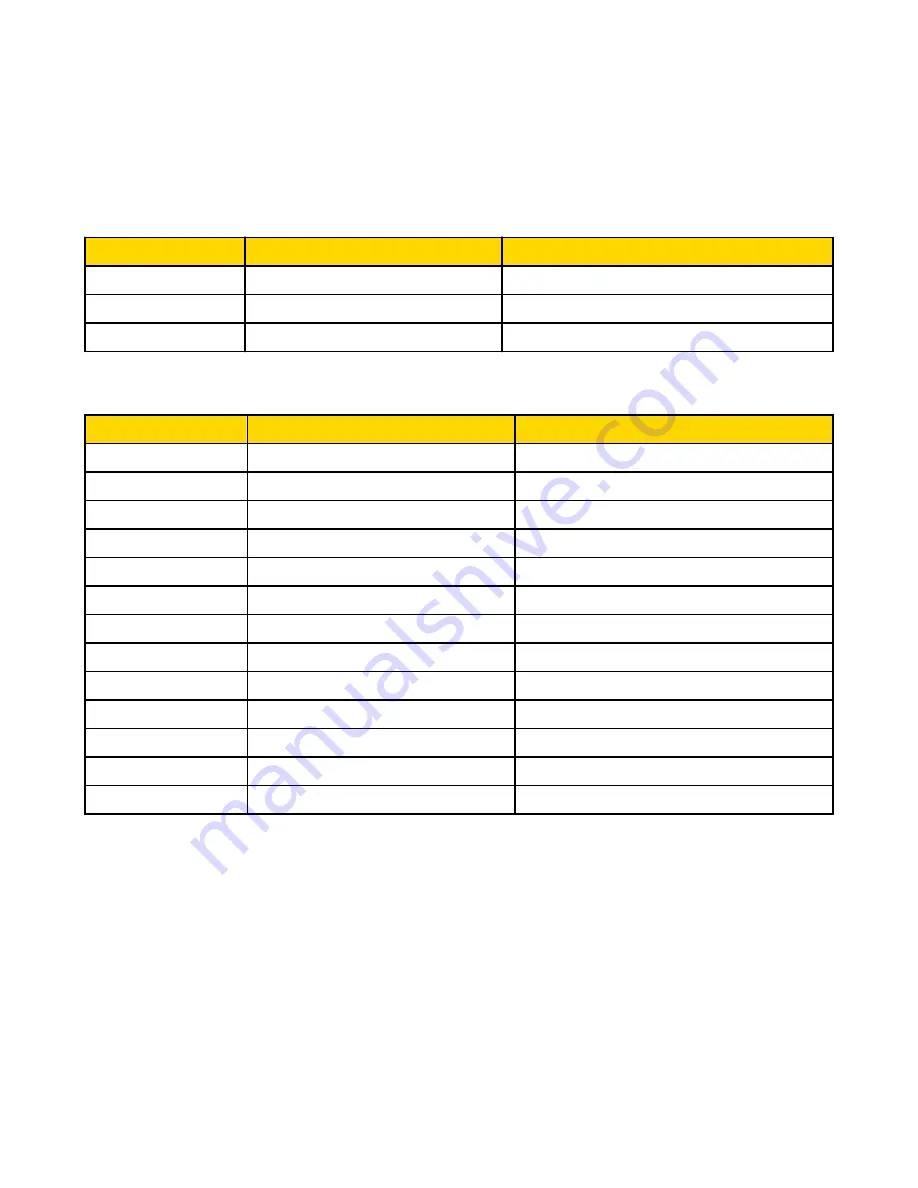

8.4.2 Assembly Objects

Outputs from PLC

iVu_OUTPUT1 Instance 0x70 (112) - 6 Registers

WORD #

WORD NAME

DATA TYPE

0

Input Bits Register

16-bit integer

1-2

Product Change Number

32-bit integer

3-5

reserved

iVu_OUTPUT2 0x71 (113) - 240 Registers

WORD #

WORD NAME

DATA TYPE

0

Inputs Bit Register

16-bit integer

1-2

Product Change Number

32-bit integer

3-49

reserved

32-bit integer

50

Command ID

16-bit integer

51

Command Parameter Int16

16-bit integer

52-53

Command Parameter Int32

32-bit integer

54-55

Command Parameter Float

Float

56-57

String Length

32-bit integer

58-107

String Parameter

100 Byte Array

108

reserved

16-bit integer

109-110

Barcode String/Mask Length

32-bit integer

111-210

Barcode String/Mask

200 Byte Array

211-239

reserved

iVu Plus User's Manual

Online Only - rev. B

www.bannerengineering.com - tel: 763-544-3164

113