Examples

>>

get blemish_result count

\x0D\x0A

<<

OK\x0D\x0A

<<

4\x0D\x0A

>>

get blemish_result minedgelength

\x0D\x0A

<<

OK\x0D\x0A

<<

22\x0D\x0A

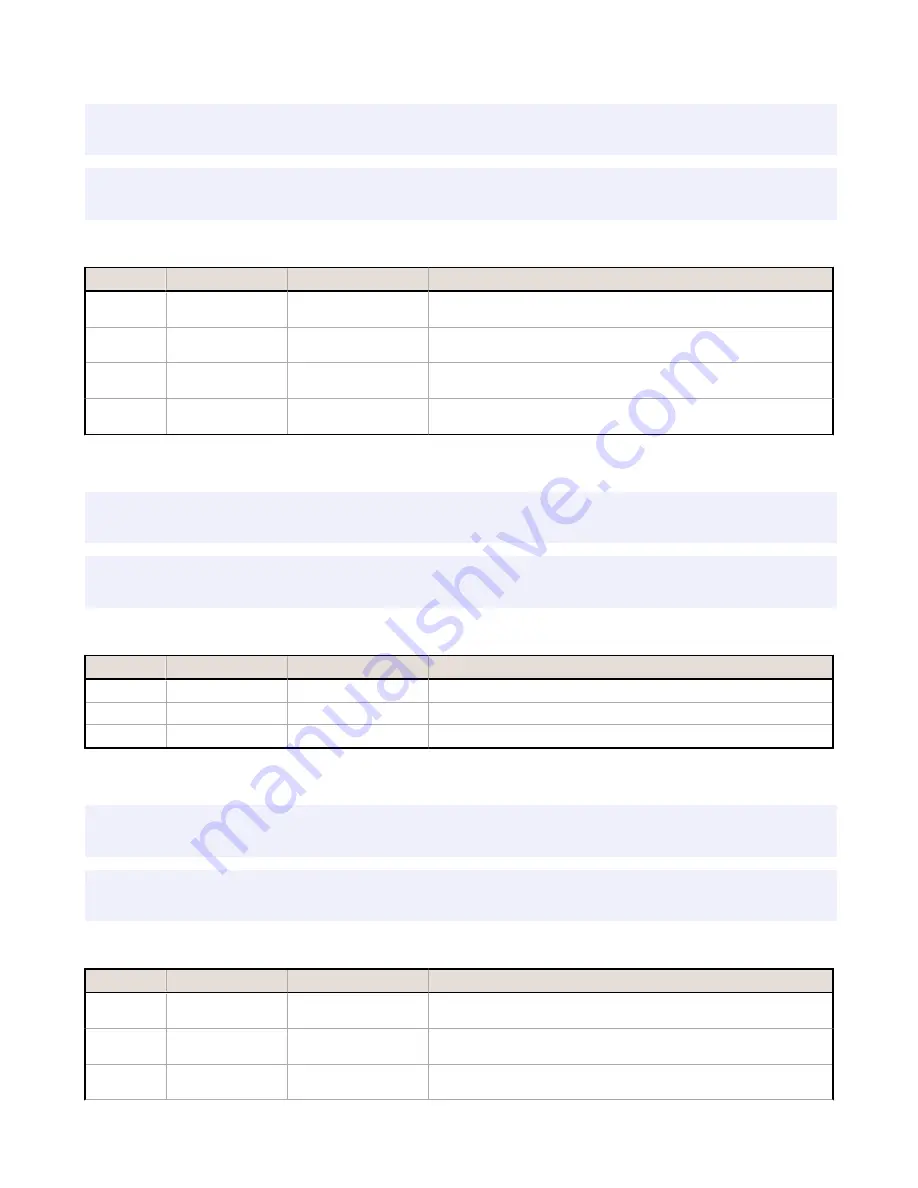

BLEMISH_HISTORY Command Group

Command

Group

Item

Description

Get

BLEMISH_HISTORY

MinCount

The minimum number of detected blemishes, since history was last

cleared.

Get

BLEMISH_HISTORY

MaxCount

The maximum number of detected blemishes, since history was last

cleared.

Get

BLEMISH_HISTORY

MinEdgeLength

The minimum detected blemish edge length, since history was last

cleared.

Get

BLEMISH_HISTORY

MaxEdgeLength

The maximum detected blemish edge length, since history was last

cleared.

Examples

>>

get blemish_history count

\x0D\x0A

<<

OK\x0D\x0A

<<

1\x0D\x0A

>>

get blemish_history maxcount

\x0D\x0A

<<

OK\x0D\x0A

<<

6\x0D\x0A

MATCH_RESULT Command Group

Command

Group

Item

Description

Get

MATCH_RESULT

Count

The number of detected matches.

Get

MATCH_RESULT

MinPercentMatch

The minimum detected match percentage.

Get

MATCH_RESULT

MaxPercentMatch

The maximum detected match percentage.

Examples

>>

get match_result count

\x0D\x0A

<<

OK\x0D\x0A

<<

1\x0D\x0A

>>

get match_result maxpercentmatch

\x0D\x0A

<<

OK\x0D\x0A

<<

6\x0D\x0A

MATCH_HISTORY Command Group

Command

Group

Item

Description

Get

MATCH_HISTORY

MinCount

The minimum number of detected matches, since history was last

cleared.

Get

MATCH_HISTORY

MaxCount

The maximum number of detected matches, since history was last

cleared.

Get

MATCH_HISTORY

MinPercent

The minimum detected match percentage, since history was last

cleared.

iVu Plus TG Gen2 Image Sensor

96

www.bannerengineering.com - Tel: 763.544.3164