CUSTOM BUILT TRACK UNITS

Chermack Machine, Inc. can provide track drive units with rubber track and built to your

exacting specifications in any size or style and for most applications. We offer in house

development and engineering and will work with your existing design, limiting customer down

time and getting your product to market faster.

TRACK CONSTRUCTION

Rubber tracks provide less ground compaction and soil damage as well as increased comfort

by less vibration and noise. They allow higher speeds, superior traction, increased pushing or

towing capability, lighter weight and are economical. They are low friction drives and result in

increased fuel economy.

Tracks are made from natural rubber which provides greater chunking and tear resistance,

wear and heat resistance and have self healing properties, which extends the track life.

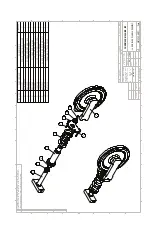

Rubber tracks are single molded assemblies consisting of a composite of steel cord,

surrounded by fabric and incorporates an interlocked forged metal link backbone. The fabric

separates the steel cord from the forged metal links which provide flexibility and strength

needed for the application.

TRACK MODEL CONFIGURATIONS

Custom under carriage assemblies ready for mounting of your operators station and your

implements can be supplied. Basic track units with mounting provisions for assembly to your

own under carriage are also possible. See page 8.

All track units are supplied with hydraulic wheel motor driven rubber tracks. The drive

sprockets engage every link of the track as opposed to every other link. This reduces the

wear on the under carriage of the machine and reduces the torque factor on the inside of the

track. This also creates for a smoother ride and less operator fatigue.

TYPICAL UNDER CARRIAGE ASSEMBLIES

Under carriages are provided with mounting arrangements for your operator station and

implements per your specification. Hydraulically "on the go" adjustable or fixed track width is

available for all under carriages.

Custom Built Track Units

Page 7