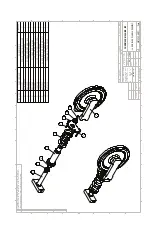

Never allow the edge of the track to ride up onto rocks, curbs, walls or other objects that

bend the track edges as shown on figure 6. This will cause the track rubber to shear or crack

along the ends of the steel inserts backbone of the track, allowing moisture and contaminents

to infiltrate the track. Eventual chunking off of the rubber will ocur and the steel cords will

corrode leading to complete failure.

OPERATING ENVIRONMENTS

Temperature

The acceptable temperature range for problem free operation of standard rubber tracks is

between -13°F[-25

C] and 131°F[+55

C]. If your application does not occur in this range

contact us for special rubber compounds.

Fuel & Oil Contamination

Fuel or hydraulic oil should not be allowed to come in contact with rubber tracks. If such

occurs, it should be immediately wiped off or rubber deterioration may occur.

Salty Environment

Salty environments should be avoided because salt and salty air erode the adhesion of

rubber to the core metals. After rubber tracks have been used in such conditions, the salt

should be removed with high pressure water spray as soon as possible.

STORAGE

If rubber tracks are stored for long periods of time, they should be kept indoors to avoid

exposure to direct sunlight and weather conditions to avoid deterioration.

Tracks should be stored on their side. Do not lay flat (as if it were on a machine) unless

support has been provided to the inside of the track. This will prevent crimping in the track

which could weaken the steel reinforcing cords and reduce track life.

Do not bend the track during storage or it may not track properly when installed.

Technical Information

Page 13