Digging over the side of the

machine compromises machine stability.

Do not apply down pressure to implements

that cause loss of traction and track spinning,

such as when using a blade to back drag. To

back drag, use the "float" mode.

Troughed and crowned surfaces place the

load on the edges of the tracks. Avoid these

surfaces when possible.

When going from flat to sloped terrain, go up

and down the slope, not along the slope,

thereby equalizing the load on each track.

When necessary to operate on slopes and only when safe, alternate directions so equal up

slope and down slope time is put on each track.

Avoid non productive travel. Transport track machines by truck or trailer to the job site to

prolong track life. Always work in both directions, do not back up to work only in one

direction.

Travel in reverse only when required. Less stress is applied to the track in forward and lug

patterns are designed for forward travel.

Drive slowly and carefully to avoid unfavorable terrain and obstacles that could damage the

track. It is recommended to make multiple large radius turns instead of making single, sharp

turns. Make "Y" turns to change direction. Avoid slipping and spinning the tracks.

Drive carefully on rough terrain and gravel surfaces. Do not drive over sharp rocks or other

obstructions that can puncture the track or concentrate forces on a small area of the track, ie,

drive to keep the full driving surface of the track in contact with the ground.

Drive to avoid turning into obstacles that could contact against the frame causing structural

damage. Avoid tight turns that force dirt and debris between the track and track support

rollers.

Do not allow obstructions to enter between the track and the track frame or roller support

mechanism. Damage will result.

Page 12

Technical Information

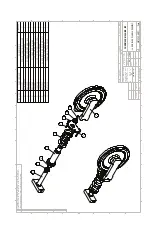

FIGURE 6

TERRAIN CONDITIONS