1-800-543-8390

•

WWW.BALLUFF.COM

6

BTL5-A/C/E/G__-M____-B/Z-S32/KA__

Micropulse Linear Position Transducer

Analog Output-Rod Style

™

4 Wiring (cont.)

5 Startup

5.1 Check connections

Although the connections are

polarity reversal protected,

components can be damaged by

improper connections and

overvoltage. Before you apply

power, check the connections

carefully.

5.2 Turning on the system

Note that the system may

execute uncontrolled movements

when first turned on or when the

transducer is part of a closed-

loop system whose parameters

have not yet been set.

Therefore make sure that no

hazards could result from these

situations.

5.3 Check output values

After replacing or repairing a

transducer, it is advisable to verify

the values for the start and end

position of the magnet in manual

mode. If values other* than those

present before the replacement or

repair are found, a correction should

be made.

* Transducers are subject to

modification or manufacturing

tolerances.

5.4 Check functionality

The functionality of the

transducer system and all its

associated components should

be regularly checked and

recorded.

5.5 Fault conditions

When there is evidence that

the transducer system is not

operating properly, it should be

taken out of service and

guarded against unauthorized

use.

Please note:

The calibration device is to be

attached to the connection end

of the transducer as shown in

Fig. 6-1. Connect the trans-

ducer to the controller. To moni-

tor the calibration procedure, a

display (controller or multimeter)

which displays the BTL voltage

or current levels is required.All

settings are done with a mag-

net within the stroke area.

Please verify that the absolute

null- and endpoints are always

within the maximum and

minimum possible output values

(value table 7-1 on page 8).

6 Calibration procedure

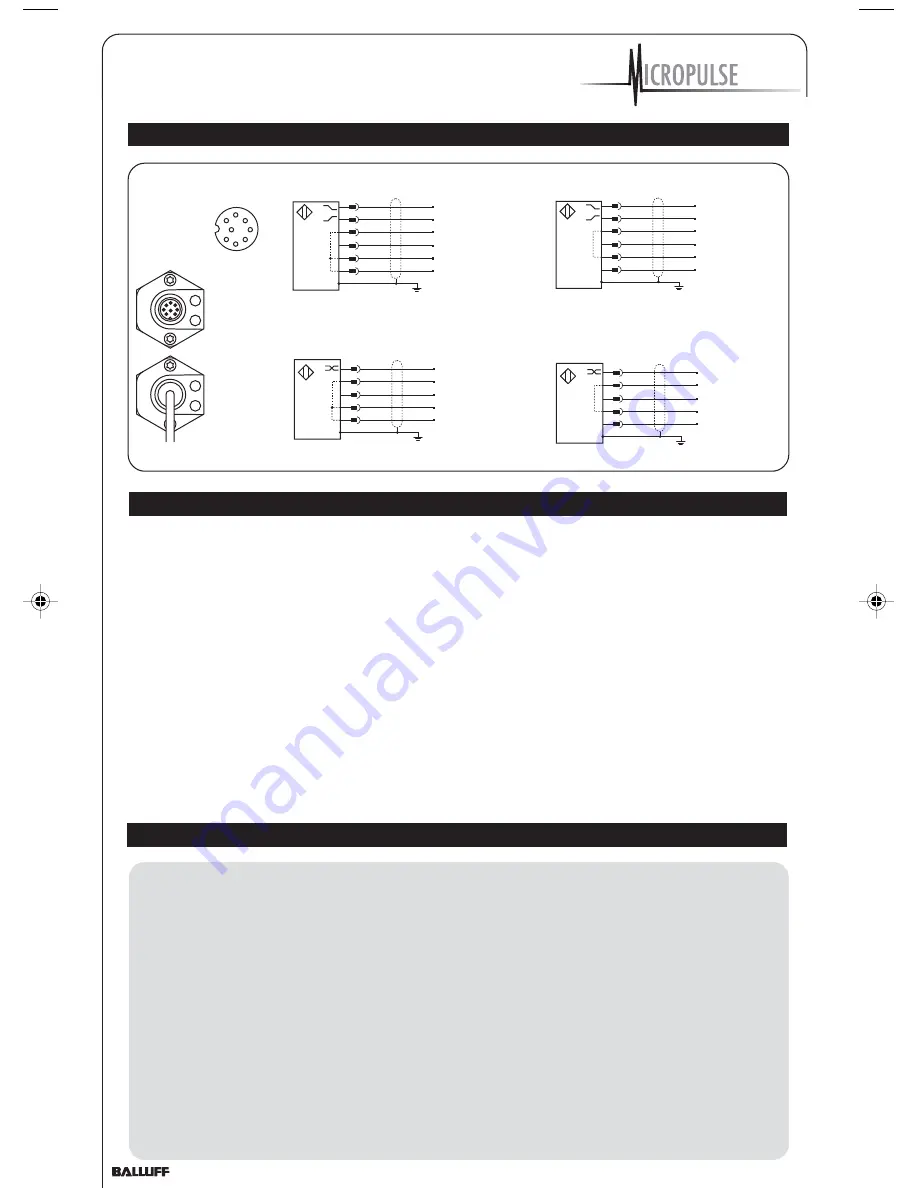

2

GY

3

PK

5

GN

7

BN

6

BU

8

WH

Analog common

Analog output, falling

Analog output, rising

Analog Voltage

24 V (A, B, G)

+24 V

GND

GND

0117a021

1

2

3

4

5

6

7

8

View of mating

connector, wiring side

2

GY

1

YE

7

BN

6

BU

8

WH

Analog common

Analog output

Analog Current

24 V (E, C)

+24 V

GND

GND

0117a023

2

GY

3

PK

5

GN

7

BN

6

BU

8

WH

Analog common

Analog output, falling

Analog output, rising

Analog Voltage

±15 V (A, B, G)

+15 V

GND

-15 V

0117a022

2

GY

1

YE

7

BN

6

BU

8

WH

Analog common

Analog output

Analog Current

±15 V (E, C)

+ 15 V

GND

-15 V

0117a024

Connector

Cable out

Any desired magnet position within

the factory set nominal stroke length

can be assigned with a null- or

endpoint. Do not however reverse the

null- and endpoints.

Once the calibration procedure is

concluded, the calibration device

can be removed to prevent accidental

changes and to store in a safe place

for the next use.

The examples shown in this handbook

refer to the two versions with 0 to 10

V and 4 to 20 mA outputs. For all

other versions the corresponding

values can be found in the value table

7-1 on page 8.

The buttons are automatically

disabled after approximately

10 minutes of non-use.

Advantages:

The display will always indicate

the current position value even

during the calibration procedure.

The last programmed values

remain stored, regardless of

whether the programming mode

is ended manually by pressing

the buttons or automatically

after 10 minutes.

Z_Analog_122003.pmd

12/11/2003, 3:47 PM

6