1-800-543-8390

•

WWW.BALLUFF.COM

4

BTL5-A/C/E/G__-M____-B/Z-S32/KA__

Micropulse Linear Position Transducer

Analog Output-Rod Style

™

0.5

74

12

~ 27

~ 27

~ 53

11

Ø 6.5

25

60 ±0.5

Ø 10.2

45

SW 46

1 2

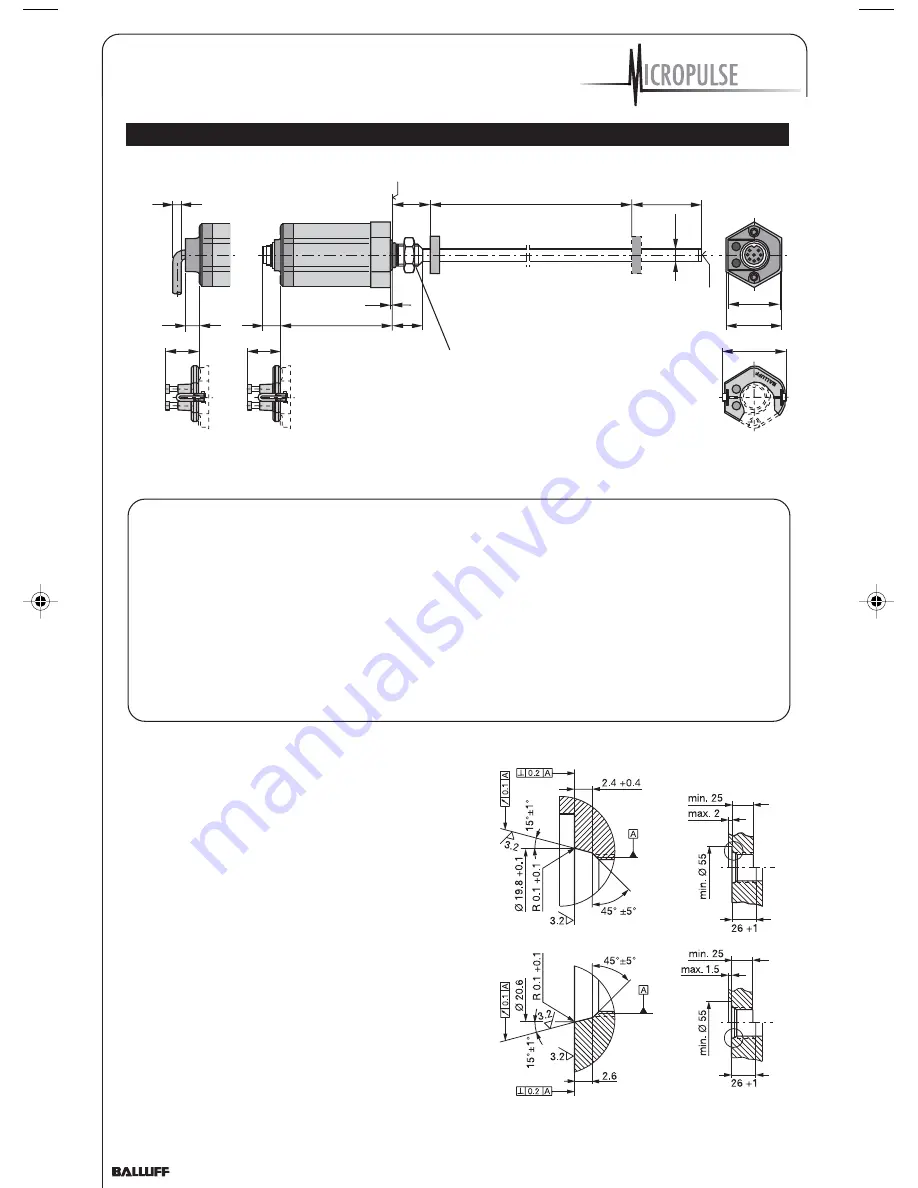

3 Installation (cont.)

Nominal length

= measuring range

Damping zone (unusable area)

Mounting

surface

Electrical connection

Magnet

Thread size: B: M18×1.5 (includes nut)

Z: 3/4"-16UNF

B: 30 mm

Z: 2"

Blind hole

M4 × 4/6 deep

Magnet

BTL5...B/Z-KA05

BTL5...B/Z-S 32

Calibration

device

Fig. 3-2: Transducer BTL5...B/Z, Dimensions

Important Installation Notes:

The contact surface of the

transducer must be

completely contacted by the

mounting surface. The O-ring

supplied must make a perfect

pressure seal, i.e. the bevel

for the O-ring must be

configured exactly as shown

in Fig. 3-3.

To achieve secure mounting,

use the proper nut for the

mounting thread. When

tightening the nut, do not exceed a

tightening torque of 100 Nm.

For horizontal mounting of

transducer with stroke lengths

greater than 500 mm, the pressure

tube should be supported or

attached at its end.

When installing in a hydraulic

cylinder, do not allow the magnet

ring to rub against the pressure

tube. The bore diameter in the

piston and cylinder

rod should be at least 13 mm.

When attaching the transducer

to magnetizable materials,

appropriate measures must be

taken to protect against

magnetic disturbances,

Fig. 3-1.

Note the recommended

distance of the transducer and

cylinder from strong, external

magnetic fields.

3.2 Transducer, Installation

The smallest permissible distance

between magnet ring and rod mounting

surface is shown in Fig. 3-2.

The transducer has either a M18×1.5

thread or a 3/4"-16UNF thread for

mounting. The sealing is carried out

with the O-ring supplied at the

flange facing.

Fig. 3-3: Threaded hole for mounting the BTL with O-ring

Threaded hole

M18×1.5 per

ISO 6149

O-ring 15.4 × 2.1

Threaded hole

3/4"-16UNF per

SAE J475

O-ring 15.3 × 2.4

Z_Analog_122003.pmd

12/11/2003, 3:47 PM

4