www.balluff.com

2

english

BTL PA0400- _ _ _ _ -B15A_010-000S92

Magnetostrictive Linear Position Sensor – Profile Style

953327_AA ∙ EN ∙ E22; subject to modification. Replaces K21.

Installation

NOTICE

Improper installation

Improper installation can compromise the function of the

BTL and result in damage.

►

Ensure that no strong electrical or magnetic fields

are present in the direct vicinity of the BTL.

►

Be sure to maintain the specified distances and

separations.

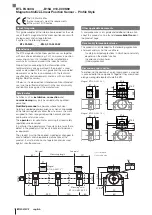

For dimensions, see figure.

Observe the following when installing the magnet:

– To ensure the accuracy of the magnetostrictive linear

position sensor, fasten the magnet to the moving

member of the machine only using non-magnetizable

screws (stainless steel, brass, aluminum).

– The moving member must guide the magnet on a

parallel line to the BTL.

– Distance A between the magnet and parts made of

magnetizable material must be kept to at least 10 mm

(see figure).

For distance B between the magnet and the BTL and for

the center offset C (see figure) the following values must be

maintained:

Magnet type

Distance B

1)

Offset C

BTL6-A-3800-2

4…8 mm

2)

± 5 mm

BTL6-A-3801-2

4…8 mm

2)

± 5 mm

1) The selected distance must remain constant over the entire stroke

length.

2) For optimal measurement results: 6…8 mm

The BTL is installed on a flat surface of the machine using

mounting clamps or cuffs (available accessories). Any

orientation is permitted. Note the recommended spacing

for the location of clamps or cuffs (see figure).

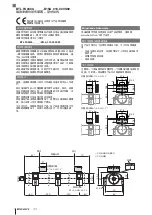

1.

Slide BTL into the mounting clamps or cuffs.

2.

Align BTL slot in the direction of the magnet(s)!

3.

Attach the BTL to the base (tighten screws in clamps

or cuffs to max. 4 Nm tightening torque).

4.

Installing magnet (accessory).

5.

Check orientation of the BTL. If the groove does not

point in the direction of the magnet, loosen the

mounting screws and repeat steps 2 to 3.

Shielding and cable routing

Defined ground!

The BTL and the control cabinet must be at the

same ground potential.

Shielding

Observe the following instructions to ensure

electromagnetic compatibility (EMC):

– Connect BTL and controller using a shielded cable.

Shielding: Braided copper shield with minimum 85%

coverage.

– Shield is internally connected to connector housing.

Magnetic fields

The position measuring system is a magnetostrictive

system. Ensure that there is sufficient distance between

the BTL and the transducer/holding cylinder and strong,

external magnetic fields.

Cable routing

Do not route the cable between the BTL, controller, and

power supply near high voltage cables (inductive stray

noise is possible).

The cable must be routed tension-free.

Cable length

BTL …-B15AA/A1…

Max. 30 m

1)

BTL …-B15AE/A5…

Max. 100 m

1)

1) Prerequisite: Construction, shielding and routing preclude the effect of

any external noise fields.

Electrical Connection

The electrical connection is made via a plug connection.

See the information about

Shielding and cable

routing

.

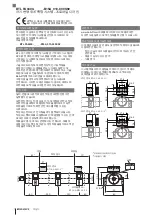

3

1

4

2

5

Pin assignment of S92 (view from

above on BTL)

Pin …-B15AA… …-B15A1… …-B15AE… …-B15A5…

1

10…30 V

2

0…10 V

10…0 V

4…20 mA

20…4 mA

3

GND

1)

4

Unassigned

2)

5

0 V

1) Reference potential for supply voltage and EMC-GND.

2) Unassigned leads that are not used can be connected to the GND on

the controller side but not to the shield.