4-2

Chapter 4. TROUBLESHOOTING

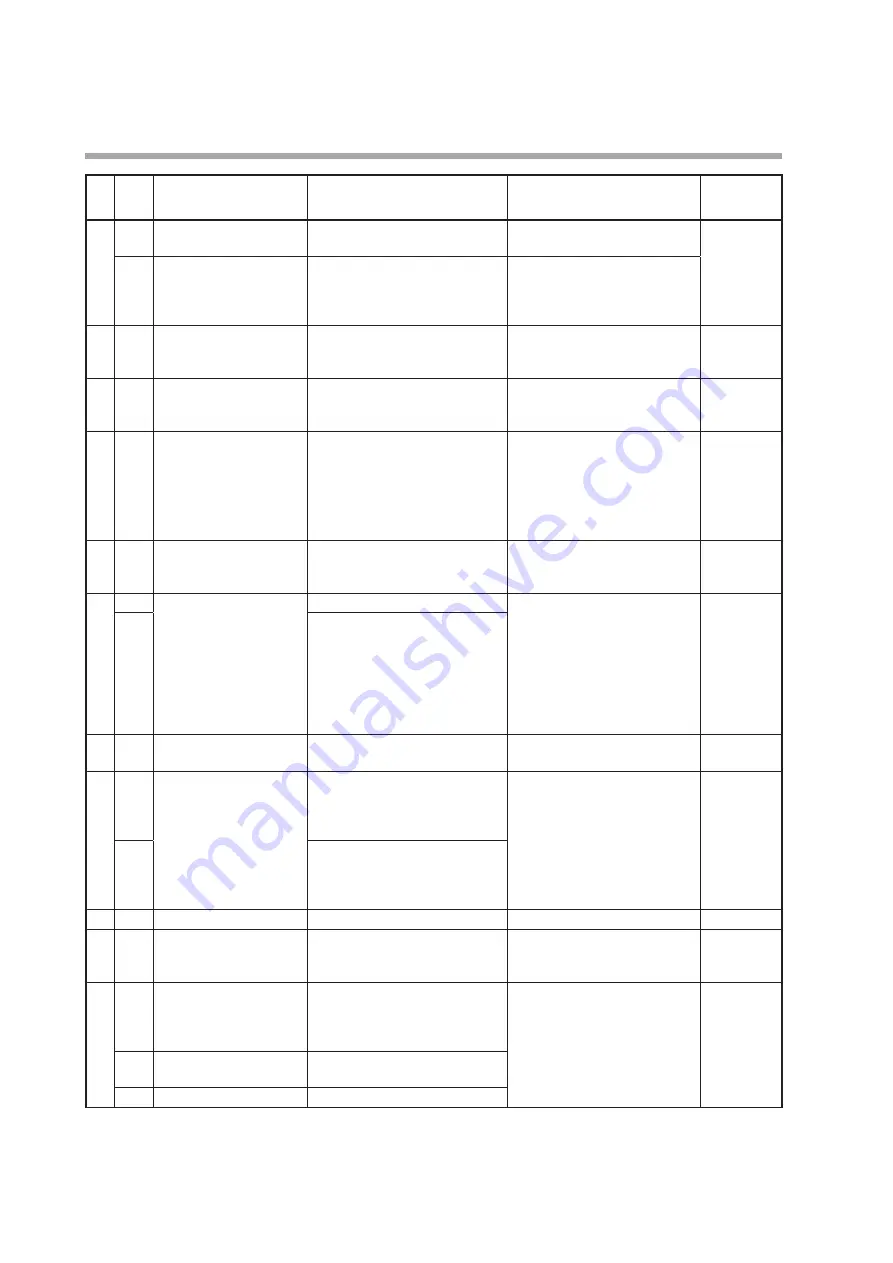

No. Type

Description

Likely cause

Corrective action

Automatic

recovery

1

Wn Empty (flow path not full) The flow path of this device has

not been full for some time.

Fill the flow path with the fluid.

✓

Inf Flow rate measurement

error

A flow rate measurement error

occurred due to a cause such as

bubbles in the flow path of the

device.

Check for problems in the

installation environment or

instrumentation.

2

Wn Accuracy-guaranteed

flow rate exceeded

Fluid is flowing at a rate greater

than the rated (accuracy-

guaranteed) flow rate.

Use this device within the rated

flow rate range.

✓

3

Wn Analog output range

exceeded

The rated flow rate was exceeded,

or an analog output correction

parameter value is invalid.

Use this device within the rated

flow rate range.

Set a valid parameter value.

✓

4

Wn Parameter error

(1) Checksum error

(2) Number of write

cycles exceeded

(1) A checksum error occurred

during parameter data reading

or writing.

(2) Parameters were written more

than the specified number of

times.

(1) Write parameters again.

(2) Replace the product.

–

5

Wn Watchdog time-out

A reset by a communication

command, or malfunction due to

electrical noise, etc.

If the warning persists after

turning the power off and back

on, request repair.

–

6

Al

Flow path or circuit

temperature out of range

The sensor unit has failed.

•

Check that the fluid

temperature and the

ambient temperature meet

the specified operating

conditions.

•

If the alarm persists after

turning the power off and

back on, request repair.

–

Wn

The fluid temperature or the

ambient temperature does not

meet the specified operating

conditions.

7

Al

Measurable flow rate

exceeded

The flow rate is greater than 115

% of the measurable range.

Use this device within the rated

flow rate range.

✓

8

Al

Totalizer pulse output

error (flow over range)

When totalizer pulse was being

output, the flow rate exceeded

the rated measurable range for a

certain period of time.

Use this device within the rated

flow rate range.

✓

Wn

When totalizer pulse was being

output, the flow rate far exceeded

the rated measurable range for a

certain period of time.

9

–

(Not used)

–

–

–

10

Al

Heater control error

The heater, temperature sensor,

or electric circuit has failed, so the

heater cannot be controlled.

If the alarm persists after turning

the power off and back on,

request repair.

✓

11

Er

Parameter error

A type of parameter not

supported by this device, or

an illegal parameter value, was

downloaded by the loader.

If the error, alarm, or information

persists after changing the

parameter and turning the

power off and back on, request

repair.

–

Al

Parameter mismatch

Parameter values are abnormal,

etc.

Inf Out-of-range parameter

Parameter values are out of range.