Owner Installation Instructions

GDO-10V1 Toro

®

19

Safety Obstruction Force Test

Wood (40 mm high)

WARNING!

Take care when testing or adjusting

the Safety Obstruction Force. Excessive force

may cause SERIOUS PERSONAL INJURY and/or

PROPERTY DAMAGE.

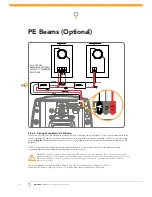

Step 8.1 - Testing Close Cycle

Press the OPEN button to open the door

.

Place a piece of timber approximately 40 mm high

on the fl oor directly under the door

(Fig. 17).

Press the CLOSE button to close door. The door

should strike the object and start to re-open.

Step 8.2 - Testing Open Cycle

Press the CLOSE button to close the door

.

Press OPEN button to open the door. When the

door reaches approximately half open point, grab

the bottom rail of the door fi rmly and the door

should stop.

If the door does not reverse readily when closing, or

stop when opening, the force may be excessive and

need adjusting, refer Adjusting Safety Obstruction

Forces .

DANGER!

If the door fails these tests, put the

opener into manual mode, only operate the door

by hand and call for service.

Load Graph

After limit setup every time door opens or close the

load graph will be display on the LCD screen. Each

bar indicate 10% power used by the door.

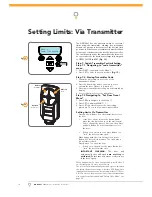

Door Reverse Time After Close Obstruction

Normally after close obstruction the door will fully

open to its open position. After close obstruction

the open cycle can be reduced from 5 sec to its full

open position.

a.

b.

c.

a.

b.

c.

17

fi g

Parameter

Min

Max

Default

Step

Unit

Menu No.

Reverse Time After Close Obstruction

5.0

Fully

Open

Fully

Open

1

Sec

2.3