G

ONLY USE THE LIFT FOR ITS DESIGNED PURPOSE. THE MANUFACTURER SHALL NOT BE

LIABLE FOR ANY INJURY OR DAMAGE TO PEOPLE, VEHICLES OR ANY OTHER OBJECTS

RESULTING FROM IMPROPER OR UNAUTHORISED USE OF THE LIFT

G

FOLLOW ALL APPLICABLE HEALTH REGULATIONS AND SAFETY STANDARDS WHEN

WORKING WITH THE LIFT.

2.4 The weight of the vehicle

The maximum loading capacity is not exceeded.

ALM-6040FL

MAX. 6.000 Kg.

ALM-10040FL

MAX. 10.000 Kg.

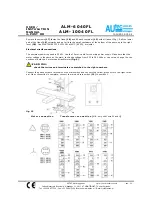

2.5 Pictograms on lift (fig. 2)

IN THE EVENT OF THESE PICTOGRAMS BEING DAMAGED, THEY MUST BE REPLACED BY NEW ONES AVAILABLE

FROM Autec - SUN / VLT Equipment.

1

OB904-09

7

OB901-ENSKA

3

OB904-10

8

OB901-DFSP

4

OB904

9

OB901-24000

5

OB905-EDNL

10

OB904-08

6

OB903-002

11

OB901-4000

Control unit.

en/TA-11-ALM-6040/10040FL

pag.: 8

ISSUED 26-05-04

A L M - 6 0 4 0 F L

A L M - 1 0 0 4 0 F L

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

11

10

7

9

8

2

1

4

3

5

6

11

11

11

fig. 2

USER /

INSTALATION

MANUAL

4-POST HD

10

7

9

8