en/TA-11-ALM-6040/10040FL

pag.: 27

USER /

INSTALATION

MANUAL

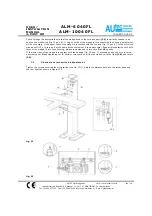

4-POST HD

ISSUED 26-05-04

A L M - 6 0 4 0 F L

A L M - 1 0 0 4 0 F L

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: [email protected]

W A R N I N G

Any connecting and disconnecting of electrical wires must always be done with the power

SWITCHED OFF

, in

other words with main switch in position “0”.

The NUMBERS SHOULD MATCH

exacly, both in the voltage

change in the motors and in connecting the terminals of the derivation boxes. During the test of lift operation, if

no movement occurs when the

RISE

or

DESCENT

button is pressed, although the teleswitch is activated and

the motors vibrate without turning, it means that two motors are wrongly connected. In this case proceed as

follows:

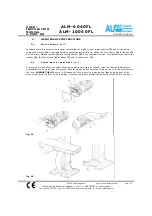

Open the control box using the appropriate key. Check that the wire numbers correspond to those on the

terminal board and these of the derivation boxes and motor boxes. If the numbers correspond, one or more

motors are connected wrongly in the terminal boards. To identify this, check individual motor rotation direction

as follows:

MOTOR 1

Disconnect the fuses from motors no. 2-3-4. Press the rise button to check that the lift rises and

press the descent button to check that it lowers.

MOTOR 2

Disconnect the fuses from motors no. 1-3-4 and check that it operates correcly.

MOTOR 3

Disconnect the fuses from motors no. 1-2-4 and check that it operates correctly.

MOTOR 4

Disconnect the fuses from motors no. 1-2-3, and repeat the test.

When you have identified the motor turning in the wrong direction, invert two wires in the motor terminal board.

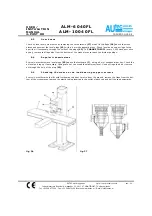

At this point you should make a complete rise and descent run with the lift fully unloaded to check that it oper-

ates correctly with all four motors. If just one motor is turning in the wrong direction, it would be over-ridden by

the other 3 but it would cause the lift to halt within 30-40 seconds because of the disconnection of the tempera-

ture relay of the motor with incorrect rotation. At this point you may identify the motor by its excessive heating.

N.B.

Any variations to the connections must always be followed by adjusting the numbers correctly to facili-

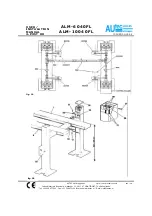

tate repair. For motor rotation direction, see fig. 11.

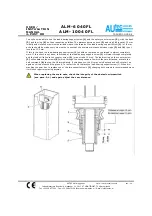

5 . 3

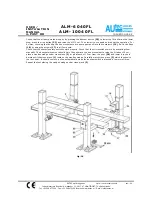

A d j u s t m e n t o f t h e d e v i c e c o n t r o l l i n g t h e w e a r o f t h e s u p p o r t s c r e w

If the post support bases are not flat, and at the same level (max. permitted difference is 20 mm), there could

be variations at the swing supports

(39)

which held the screws

(41)

. This may cause an unbalance of the

“load-bearing support screw wear” control.

Since these levels are not easily obtained, we recommend you to make the following check: press the rise but-

ton

(22)

to lift the upper plane of footboards

(7)

and

(8)

600-700 mm from the ground and loosen the screws

(37)

to remove the covers

(36)

from all four posts. Remove the screws

(17)

to free the flaps

(18)

turn them

upside down and let each fall behind its post.