Section 03

ENGINE

Subsection 05

(COOLING SYSTEM)

VMR2004_128_03_05A.FM

03-05-9

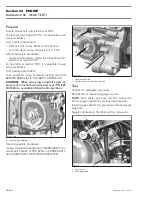

1. Special area for oil seal removal

Inspection

Inspect water pump gear for wear and damage on

the snap mechanism to the needle pin. Replace if

damaged.

Water pump shaft with rotary seal must rotate free-

ly. Otherwise, replace it.

NOTE:

When removing water pump shaft, always

replace together retaining ring, oil seal, water pump

shaft with rotary seal with new parts.

Installation

For installation, reverse the removal procedure.

However, pay attention to the following.

NOTE:

Never use oil in the press fit area of the oil

seal and rotary seal.

Push water pump shaft oil seal in place by using the

oil seal pusher (P/N 529 035 757).

1. Oil seal for the water pump shaft

2. Oil seal pusher (P/N 529 035 757)

3. Handle for insertion jig (P/N 420 877 255)

It is recommended to install the water pump shaft

assembly using the water pump ceramic seal in-

staller (P/N 529 035 766).

NOTE:

The water pump shaft assembly has to be

pushed using the outside area of the rotary seal.

1. Surface to push water pump shaft assembly in place

CAUTION:

Never use a hammer for the rotary

seal installation. Only use a press to avoid dam-

aging the ceramic component.

1

R400motr146A

1

R400motr147A

3

2

1

R400motr150A