Section 03

ENGINE

Subsection 09

(CYLINDER AND HEAD)

VMR2004_132_03_09A.FM

03-09-25

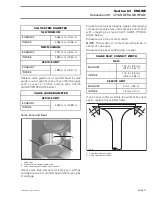

1. Piston

2. Feeler gauge

Ring End Gap

Measure position for ring end gap in the area of 8

to 16 mm (.315 to .630 in) from top of cylinder.

NOTE:

In order to correctly position the ring in the

cylinder, use piston as a pusher.

Using a feeler gauge, check ring end gap. Replace

ring if gap exceeds above described specified tol-

erance.

Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

NOTE:

First install spring and then rings of oil

scraper ring.

Install the oil scraper ring first, then the lower com-

pression ring with the word “N and TOP “ facing

up, then the upper compression ring with the word

“N and TOP“ facing up.

1. Upper compression ring

2. Lower compression ring

3. Oil scraper ring

CAUTION:

Ensure that top and second rings are

not interchanged.

NOTE:

Use a ring expander to prevent breakage

during installation. The oil ring must be installed by

hand.

Check that rings rotate smoothly after installation.

Space the piston ring end gaps 120° apart and do

not align the gaps with the piston pin bore or the

thrust side axis.

1. DO NOT align ring gap with piston thrust side axis

2. DO NOT align ring gap with piston pin bore axis

A. 120°

RING END GAP

NEW MINIMUM

UPPER

COMPRESSION RING

0.20 mm (.008 in)

LOWER

COMPRESSION RING

0.20 mm (.008 in)

OIL SCRAPER RING

0.20 mm (.008 in)

NEW MAXIMUM

UPPER

COMPRESSION RING

0.40 mm (.014 in)

LOWER

COMPRESSION RING

0.40 mm (.014 in)

OIL SCRAPER RING

0.70 mm (.028 in)

SERVICE LIMIT

ALL

1.5 mm (.059 in)

1

R400motr103A

2

A31C2NA

1

2

3

A31C2OA

1

2

A

A

A