Section 03

ENGINE

Subsection 10

(CRANKSHAFT/BALANCER SHAFT)

VMR2004_133_03_10A.FM

03-10-5

TIMING CHAIN GUIDE

Removal

Remove:

– engine from vehicle

(refer to REMOVAL AND INSTALLATION)

– magneto and rotor (refer to MAGNETO)

– bearing screw at the bottom of chain guide.

Pull the chain guide downward to remove it.

Inspection

Check chain tensioner guide for wear, cracks or other

damages. Replace if necessary.

Installation

Clean bearing screw threads then apply Loctite 243

on the screw threads.

Install the guide in crankcase housing then torque

bearing screw to 10 N•m (89 lbf•

in

).

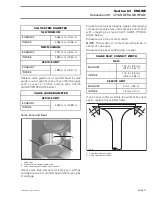

1. Chain tensioner guide

2. Bearing screw

3. Crankcase MAG side

Reinstall all removed parts in accordance with the

proper installation procedures.

CRANKCASE

To reach the balancer shaft and the crankshaft, it

is necessary to separate the crankcase.

The procedures to remove, inspect and install the

balancer shaft and the crankshaft are explain fur-

ther in this section. For all gearbox parts refer to

GEARBOX).

Removal

Remove:

– engine from vehicle

(refer to REMOVAL AND INSTALLATION)

– magneto housing cover and rotor

(refer to MAGNETO SYSTEM)

NOTE:

Oil pump removal from crankcase MAG

side not necessary, but recommended to see con-

dition of oil pump (refer to LUBRICATION SYS-

TEM).

– output shaft (refer to GEARBOX)

– timing chain (see TIMING CHAIN above)

– cylinder head and cylinder

(refer to CYLINDER AND HEAD)

– drive pulley (refer to CVT, see DRIVE PULLEY).

Measure axial clearance between the crankshaft

no. 3

and crankcase PTO

no. 5

with a feeler gauge.

1. Feeler gauge

3

R400motr48A

1

2

CRANKSHAFT AXIAL CLEARANCE

MINIMUM (new)

0.1 mm (.0039 in)

MAXIMUM (new)

0.4 mm (.0157 in)

1

R400motr22A