2920 1257 04

40

Instruction book

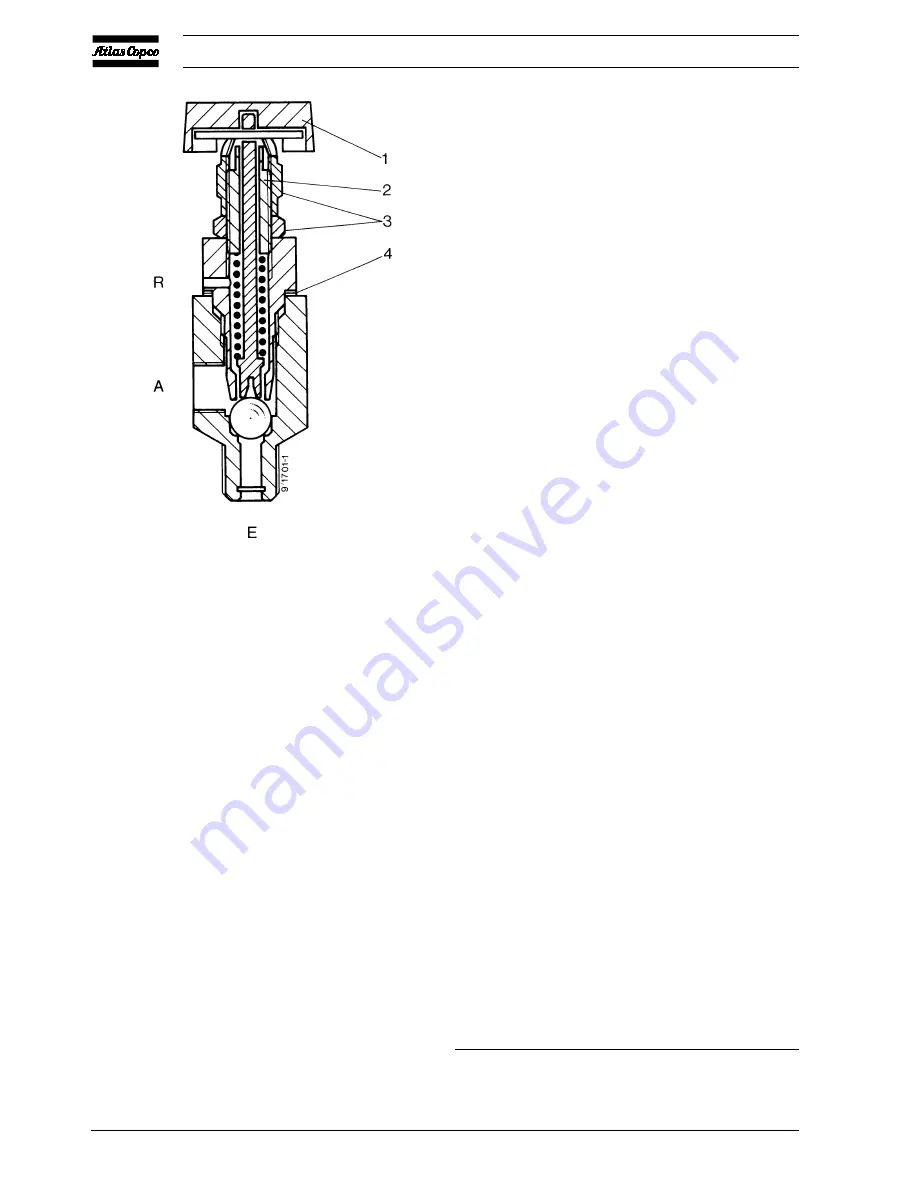

Setting of the pilot valve

The maximum pressure is controlled by adjusting screw (2):

-

Loosen handle (1) and the two nuts (3).

-

Turn the adjusting screw (2) clockwise to increase the

maximum pressure.

-

The pressure difference can be increased by removing one

or more shims (4).

-

Fit the two nuts (3) and handle (1) in their original position.

5.7 Safety valve (SV-Figs. 1.4, 1.5 and

1.8) 1)

Replace the valve if it does not open at the correct pressure.

No adjustments are allowed.

A

Control air to unloader

E

Compressed air from pulsation dampers

R

Vent hole

1

Unloading handle

2

Pressure adjusting screw

3

Nuts

4

Shims

Fig. 5.8 Pilot valve on LE/LT Trolley

Testing on LE/LF/LT

1. Close the air outlet valve, depressurize and disconnect the

hose or pipe from the valve.

2. Start the compressor and run it until it stops automatically.

3. Switch off the voltage.

Remove the cover from the air pressure switch and, with

the air receiver now under pressure, turn the adjusting knob

or screw one turn clockwise to increase the stopping

pressure (see also sections 5.4/5.5). Reinstall the cover.

4. Switch on the voltage, slightly open the outlet valve and

start the compressor.

5. Gradually close the outlet valve while checking the air

pressure gauge. If the safety valve has not opened at the

pressure specified in section 7, it must be replaced by a

new one. If the compressor unloads before the specified

opening pressure is reached, repeat the procedure as

mentioned from step 3.

6. Readjust the unloading pressure as described in sections

5.4 and 5.5.

7. Reconnect the hose or pipe to the closed air outlet valve.

Testing on LE/LF/LT Trolley

1. Close the air outlet valves, depressurize and disconnect

the hoses from the valves.

2. Loosen the red handle of the pilot valve (1-Fig. 5.8) and

the two nuts (3).

3. Open outlet valve (AV1-Fig. 1.16) a fraction. Start the

compressor.

4. Gradually turn adjusting screw (2-Fig. 5.8) clockwise while

checking pressure gauge (Gp-Fig. 1.16).

If the safety valve has not opened at the pressure specified

in section 7, it must be replaced by a new one.

5. Readjust the normal working pressure after testing. Consult

section 5.6.

6. Fit nuts (3-Fig. 5.8) and handle (1) in their original

positions.

5.8 Relief valve (8-Fig. 1.1) on LF55/75,

LE75 up to -150 and LT

The relief valve protects the LP side of the compressor. No

adjustments are allowed.

Remove the relief valve and fit a 3/8 inch B.S.P. plug instead.

Remove the safety valve from the air receiver and replace it

by the relief valve. The latter can then be tested at increasing

air receiver pressure after the compressor has been started

with open air outlet valve. If the valve has not opened at the

pressure specified in section 7, it must be replaced by a new

one. Reinstall the valves in their respective places after testing.

Footnote chapter 5

1) Not on Compressor Block/Power Pack

Summary of Contents for LE110

Page 11: ...2920 1257 04 11 Instruction book Fig 2 2 Dimension drawing LE LT55 75 and LF40 55 Power Pack ...

Page 19: ...2920 1257 04 19 Instruction book Fig 2 10 Dimension drawing LE LT15 up to 40 Unsilenced Pack ...

Page 21: ...2920 1257 04 21 Instruction book Fig 2 12 Dimension drawing LE LT15 up to 150 with CD dryer ...