® Copyright by ATH-Heinl GmbH & Co. KG, 2014, All rights reserved /Misprint and technical changes reserved / Issue: 12/2014

- 18 -

Position the wheel in that way so that the clamping jaws only touch the tire.

Push the rim down as far as the rim edge touch the clamping jaws.

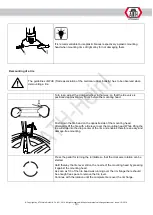

In case of extremely rigid tires an optional assist arm can be ordered for

refitting the machine.

Press the pedal for clamping the rim and then remove the feet. The wheel will

be clamped.

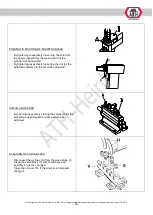

Adjustment of the mounting head

In case of working predominantly with big wheels until 24“ respectively small 8“ wheels it is

recommendable to adapt the mounting head adjustment to the rim diameter.

The adjustment of the mounting head will be explained in the chapter MAINTENANCE.

Tilt respectively swivel the mounting head into the working position and

loosen the arrestor for positioning and putting it manually on the rim edge. In

this connection the guiding roll (3) respectively the plastic grinding part (for

light alloy rims) may touch the corresponding rim outline.

By arresting the mounting head it will remove automatically away from the rim

in height and distance. At the type M32 there must be additionally fitted the

adjustment wheel for the swinging arm.

The adjustment of the automatic distance is explained in the subitem

„Maintenance and Service works“.