® Copyright by ATH-Heinl GmbH & Co. KG, 2014, All rights reserved /Misprint and technical changes reserved / Issue: 12/2014

- 25 -

Maintenance instructions

The machine has to be maintained and cleaned regularly, independent from the dirt.

.

Afterwards the machine has to be treated with a cleaning agent (e.g. oil or wax spray). Do not use

cleaning agents which are harmful for the skin

IF THE NAMED POINTS WILL NOT BE FULFILLED, THEN THE WARRANTY CLAIM EXPIRES

Immediately

-

All liquids and other dirt on the machine has to be removed immediately.

-

Damages on the surface protection (paintwork/cinc and so on) has to be refinished.

Daily

-

Cleaning

-

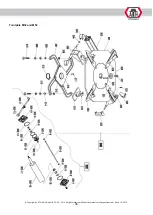

Removing of dirt and tire parts from the clamping jaws

Weekly

-

Check the tightness of all screws.

-

Lubrication of the slides of the clamping jaws with grease according to ISO VG 68 Viscosity, ISO

HG category.

Monthly

-

Service on the compressed air maintenance unit (see „maintenance and service instructions“.

Quarterly

-

Lubrication (grease pistol) of pedals on the valve blocks and guiding pieces in the interior of the

machine.

-

Removing the collected dirt in the interior of the machine.

-

Checking of pneumatic cylinder and stopper of the tilting function.

-

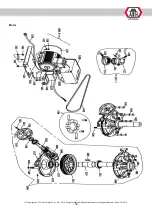

Checking of the holder of motor and gear for stability.

-

Checking of the tension of the V-belt between motor and gear.

-

Checking of the pneumatic cylinder for the rim tension and bead breaking function.

-

Lubrication of guiding cavity for the clamping jaws (rim tension) and checking of fixation

-

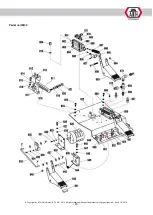

Checking of the clamping mechanism of the mounting tower for fixation and function

-

Lubrication of the clamping cylinder (locking cylinders) of the mounting tower

-

Lubrication and adjustment of the guide roll on the mounting tower

-

Lubrication and adjustment of guide plates on the mounting tower

-

Lubrication of guide parts on the mounting tower