[38]

5.6.

Angle Measure

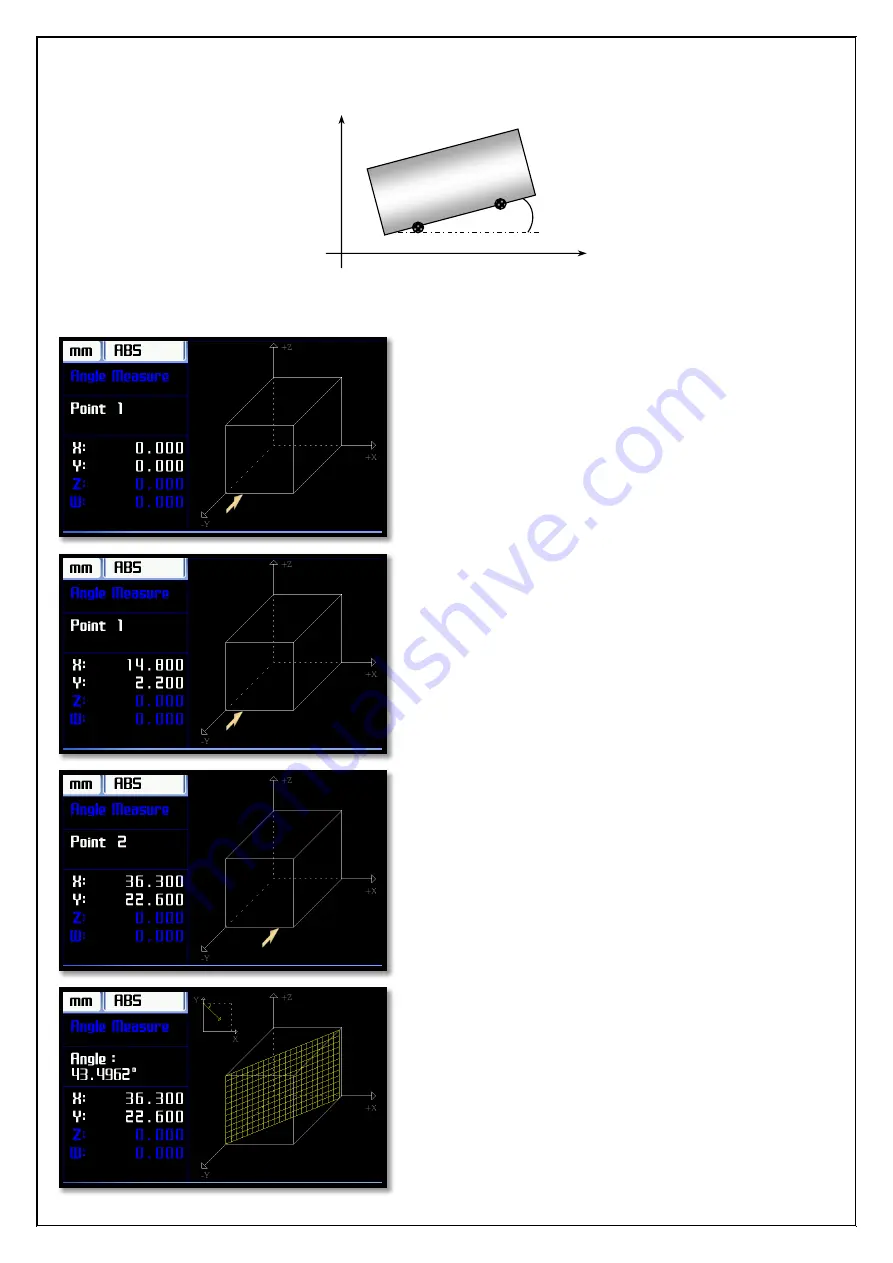

The angle of the workpiece can be measured with Angle Measurement function.

To enter the the Angle Measure Function, press "5" button while on the function screen or to reach the "Angle

Measure” with arrow keys then press "ENT" button.

When the function startup the simulation screen will be

open like a the side. The measuring axis should be

chosen with up and down arrow buttons.The selected

axis will be displayed as a white in the list on the left.

To angle measurement of workpiece, from the edge of

the workpiece must be taken measurement of two

reference points.

When the function opens firstly the referance point

which measurements must be taken is presented as

representative.

When insert the end of the reference point to one the

“ENT” button is pressed.

Simulation screen is updated for the reference point 2.

Insert the end of the reference point is brought 2 and in

order to show of angle the press "ENT" button.

X

Y

Point 1

Point 2

Angle

Workpiece

Insert the end of the 2nd reference point after the

“ENT” button is pressed, the taper angle of the object

will be shown on the screen.